Sensors and Instrumentation

These systems utilize hydraulic or pneumatic actuators, valves, pumps, and other components to perform various tasks in steel manufacturing processes.

- Home

- Products

- Spares and Consumables

- Sensors and Instrumentation

Our Products

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. or just call us now.

Sensors and Instrumentation Overview

Hydraulic and pneumatic systems are crucial components in the steel manufacturing industry, providing power transmission and control through the use of fluids or compressed air. These systems utilize hydraulic or pneumatic actuators, valves, pumps, and other components to perform various tasks in steel manufacturing processes.

Range of Sensors and Instrumentation

Temperature Sensors

Temperature sensors, such as thermocouples and resistance temperature detectors (RTDs), are used to measure and monitor temperatures in various steel manufacturing processes. They are designed to withstand high temperatures and provide precise temperature measurements for controlling heating, cooling, and annealing processes.

Pressure Sensors

Pressure sensors are utilized to measure and monitor pressure levels in hydraulic systems, pneumatic systems, and other applications. They ensure proper pressure control and help prevent equipment failure or damage due to excessive pressure.

Level Sensors

Level sensors are employed to measure and monitor liquid levels in tanks, vessels, and other containers. They ensure accurate level control and prevent overflows or shortages of liquids used in steel manufacturing processes.

Flow Sensors

Flow sensors are used to measure and monitor the flow rates of liquids and gases in pipes and conduits. They provide critical information for maintaining optimal flow rates in cooling systems, lubrication systems, and other fluid handling processes.

Position and Displacement Sensors

Position and displacement sensors, such as linear encoders and proximity sensors, are utilized to measure and monitor the position, movement, and alignment of steel components and equipment. They ensure precise positioning, alignment, and control in tasks such as material handling, machining, and assembly.

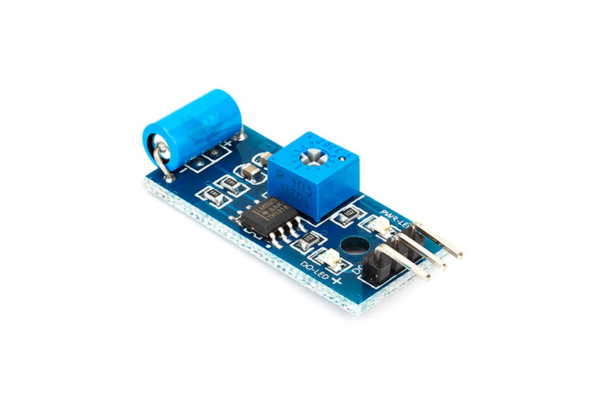

Vibration Sensors

Vibration sensors are employed to measure and monitor vibrations in machinery and equipment. They help detect irregularities, mechanical faults, and potential failures in rotating equipment like motors, pumps, and rollers.

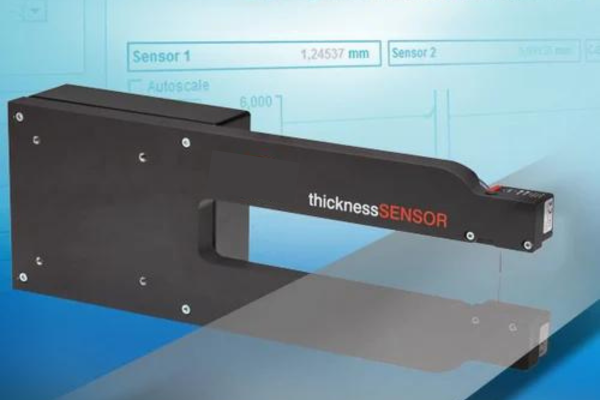

Thickness Sensors

Thickness sensors are used to measure and monitor the thickness of steel sheets, plates, and other materials during production processes. They ensure the accuracy and uniformity of thickness for quality control and compliance with specifications.

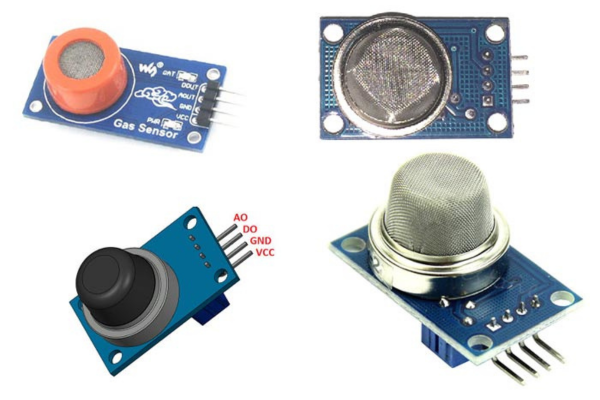

Gas and Chemical Sensors

Gas and chemical sensors are utilized to detect and monitor the presence and concentration of gases, such as oxygen, carbon dioxide, and harmful fumes in the steel manufacturing environment. They help maintain safe working conditions and ensure compliance with environmental regulations.

Applications of Hydraulic System

Process Monitoring and Control

Sensors and instrumentation enable real-time monitoring and control of critical parameters in steel manufacturing processes, such as temperature, pressure, flow, and level. They provide data for process optimization, quality control, and predictive maintenance.

Quality Assurance

Sensors are used to measure and monitor parameters that affect the quality of steel products, such as temperature during annealing or coating processes, thickness during rolling, and alignment during machining. They help ensure the consistency, uniformity, and adherence to specifications for high-quality steel products.

Safety and Environmental Monitoring

Gas and chemical sensors are employed to monitor the presence of harmful gases and fumes in the steel manufacturing environment. They help maintain safe working conditions and ensure compliance with environmental regulations.

Equipment Condition Monitoring

Vibration sensors and other condition monitoring instruments are used to detect abnormalities, mechanical faults, and potential failures in machinery and equipment. They enable predictive maintenance, reducing downtime and optimizing equipment performance.

Key Features and Benefits

Accurate and Reliable Data

Sensors provide accurate and reliable data on critical parameters, enabling precise monitoring and control of steel manufacturing processes. They help identify deviations, optimize process parameters, and improve product quality.

Real-time Monitoring & Control

Sensors and instrumentation provide real-time monitoring and control of key parameters in steel manufacturing processes. They offer immediate feedback on process conditions, allowing for quick adjustments and interventions to ensure optimal performance.

Process Optimization

By capturing precise data on temperature, pressure, flow, and other parameters, sensors and instrumentation facilitate process optimization. They help identify inefficiencies, bottlenecks, and areas for improvement, leading to increased productivity and cost savings.

Quality Assurance

Sensors play a crucial role in quality assurance by ensuring that critical parameters are within specified ranges. They enable continuous monitoring of temperature, thickness, alignment, and other factors that affect the quality of steel products.

Predictive Maintenance

Vibration sensors and other condition monitoring instruments aid in predictive maintenance practices. By detecting early signs of equipment deterioration or abnormalities, they allow for proactive maintenance to prevent unplanned downtime and costly breakdowns.

Safety and Environmental Compliance

Gas and chemical sensors ensure the safety of workers by monitoring the presence of hazardous gases or fumes in the steel manufacturing environment. They help maintain compliance with environmental regulations by detecting and controlling emissions.

Data-driven Decision Making

Sensors and instrumentation provide valuable data that can be analyzed and used for data-driven decision making. The insights gained from sensor data can inform process improvements, equipment upgrades, and overall operational strategies.

Integration with Automation Systems

Sensors and instrumentation seamlessly integrate with automation systems, enabling centralized monitoring and control of steel manufacturing processes. They can communicate with programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems, facilitating efficient data collection and analysis.

In summary, sensors and instrumentation are essential components in the steel manufacturing industry, enabling real-time monitoring, control, and optimization of critical parameters and processes. They provide accurate and reliable data for quality assurance, safety, environmental compliance, and predictive maintenance. With their ability to capture real-time data, sensors and instrumentation support data-driven decision making and integration with automation systems, contributing to improved efficiency, productivity, and cost-effectiveness in steel manufacturing operations.