Gears and Gearboxes

Our range of gears and gearboxes encompasses different types and configurations designed to meet the specific requirements of steel manufacturing applications.

- Home

- Products

- Spares and Consumables

- Gears and Gearboxes

Our Products

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. or just call us now.

Gears and Gearboxes Overview

Gears and gearboxes are essential components in the steel manufacturing industry, responsible for transmitting power and torque, controlling speed, and providing precise motion control in various machinery and equipment. Our range of gears and gearboxes encompasses different types and configurations designed to meet the specific requirements of steel manufacturing applications.

Range of Gears and Gearboxes

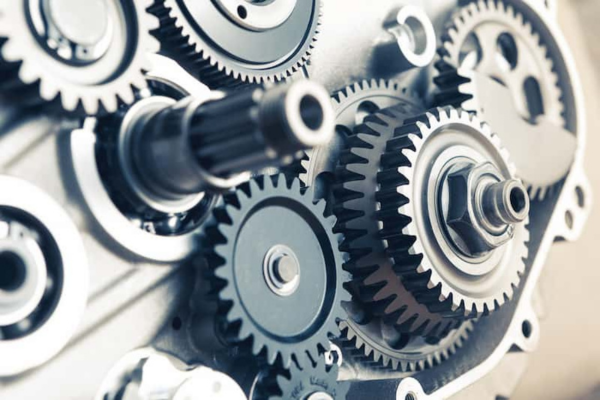

Gears

Gears are toothed mechanical components that transmit power from one rotating shaft to another, enabling speed reduction, torque multiplication, or motion control. They come in various types, including spur gears, helical gears, bevel gears, worm gears, and planetary gears, each suited for specific applications and operating conditions. Gears are typically made of high-strength materials, such as alloy steels, to withstand the high loads, shocks, and vibrations encountered in steel manufacturing processes. Precise machining and tooth profile design ensure smooth and efficient power transmission, minimizing noise, wear, and energy loss.

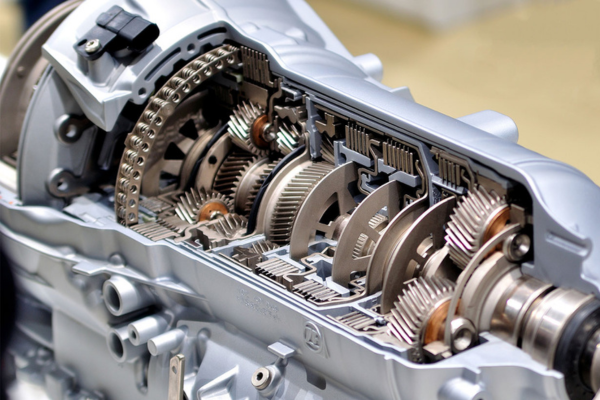

Gearboxes are mechanical devices that house one or more gears, providing speed reduction, torque multiplication, and direction control in machinery and equipment. They allow the adjustment of output speed and torque to match the requirements of different steel manufacturing processes. Gearboxes can be classified into various types, including parallel shaft gearboxes, helical gearboxes, bevel gearboxes, and planetary gearboxes, each offering specific advantages in terms of compactness, efficiency, and load-bearing capacity. Gearboxes are constructed with robust housings and precision-engineered gears to ensure reliable and long-lasting performance in demanding steel manufacturing environments. Lubrication systems are often incorporated to minimize friction and wear, ensuring smooth gear operation and extended service life.

Gearbox

Applications of Gears and Gearboxes

Rolling Mills

Gears and gearboxes are extensively used in rolling mills to drive the rolls and control the speed and tension during the rolling process. They enable the precise control of material thickness, shape, and surface finish, ensuring the production of high-quality steel products.

Conveyor Systems

Gears and gearboxes are employed in conveyor systems to provide motion control and speed adjustment. They enable the efficient and reliable movement of steel materials throughout the production facility, optimizing productivity and material handling.

Cranes and Hoists

Gears and gearboxes are utilized in overhead cranes, gantry cranes, and hoists to provide the necessary lifting and movement capabilities. They enable the safe and precise positioning of heavy steel materials, such as coils or ingots, during the manufacturing process.

Furnaces and Kilns

Gears and gearboxes are employed in furnace and kiln applications to control the rotation and movement of the charging and discharging mechanisms. They ensure proper alignment, speed control, and positional accuracy, facilitating efficient heat treatment and material handling.

Key Features and Benefits

Power Transmission Efficiency

High-quality gears and gearboxes minimize power loss during transmission, ensuring efficient energy utilization in steel manufacturing processes. Precise gear tooth engagement and proper lubrication contribute to optimal power transfer and reduced energy consumption.

Speed and Torque Control

Gears and gearboxes allow the adjustment of output speed and torque to match the specific requirements of steel manufacturing operations. They provide flexibility in controlling the speed of rolling mills, conveyor systems, and other equipment, allowing for precise and customized production processes.

Load Handling and Capacity

Gears and gearboxes are designed to handle heavy loads and provide reliable torque transmission in steel manufacturing applications. They ensure the smooth and controlled movement of materials, such as steel coils or ingots, throughout the production facility.

Durability and Reliability

Gears and gearboxes used in the steel industry are constructed with robust materials and undergo stringent quality control measures. They are engineered to withstand the demanding conditions of steel manufacturing, including high loads, shocks, vibrations, and temperature variations.

Motion Control and Precision

Gears and gearboxes offer precise motion control, allowing for accurate positioning and speed adjustment in steel manufacturing processes. They ensure the consistent and uniform movement of materials, resulting in precise shaping, thickness control, and product quality.

Versatility and Adaptability

Gears and gearboxes come in various configurations and sizes to suit different steel manufacturing applications and equipment requirements. Manufacturers offer customization options, such as gear ratios, input and output shaft arrangements, and mounting configurations, to meet specific process needs.

Maintenance and Serviceability

Gears and gearboxes designed for easy maintenance and serviceability help minimize downtime and ensure smooth operation. Accessible lubrication points, inspection ports, and removable covers facilitate routine maintenance and inspection tasks, enhancing equipment longevity.

Technical Support and Expertise

Reputable manufacturers of gears and gearboxes provide technical support, expertise, and guidance on selecting the appropriate products for specific steel manufacturing applications. They offer assistance in gearbox sizing, gear selection, installation, and troubleshooting, ensuring optimal performance and reliability.

In summary, gears and gearboxes are vital components in the steel manufacturing industry, enabling power transmission, speed control, and motion precision in various equipment and processes. Their durability, load handling capacity, and adaptability make them essential for rolling mills, conveyor systems, cranes, furnaces, and other applications in steel production. With their efficiency, reliability, and precise motion control capabilities, high-quality gears and gearboxes contribute to improved productivity, product quality, and operational efficiency in the steel manufacturing industry.