Filters and Filtration Systems

These systems ensure the cleanliness and purity of fluids, protecting equipment, improving product quality, and enhancing overall operational efficiency.

- Home

- Products

- Spares and Consumables

- Filters and Filtration Systems

Our Products

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. or just call us now.

Filters and Filtration Systems Overview

Filters and filtration systems play a crucial role in the steel manufacturing industry by removing impurities, contaminants, and particulate matter from various fluids and gases used in the production processes. These systems ensure the cleanliness and purity of fluids, protecting equipment, improving product quality, and enhancing overall operational efficiency.

Range of Filters and Filtration Systems

Fluid Filters

Fluid filters are used to remove solid particles, debris, and contaminants from fluids such as water, hydraulic oil, lubricating oil, and coolant. They employ various filtration media, including mesh screens, pleated filters, and depth filters, to achieve different levels of filtration efficiency.

Air Filters

Air filters are designed to purify and remove airborne particles, dust, and contaminants from the air used in steel manufacturing processes. They safeguard sensitive equipment and components, such as compressors, pneumatic systems, and air blowers, from damage and performance degradation.

Gas Filters

Gas filters are utilized to remove impurities and contaminants from gases used in various steel manufacturing applications, including oxygen, nitrogen, and argon. They protect gas control systems, burners, and sensitive equipment from clogging and damage caused by particulate matter and contaminants.

Bag Filters

Bag filters are employed to capture and separate dust particles and fine particulate matter from gas streams in steel manufacturing processes, such as blast furnaces and electric arc furnaces. They use fabric filter bags with high filtration efficiency to trap dust and prevent its release into the atmosphere.

Magnetic Filters

Magnetic filters utilize magnets to capture and remove ferrous contaminants from liquid and gas streams in steel manufacturing processes. They attract and retain ferrous particles, such as iron filings and metal shavings, preventing their circulation and potential damage to equipment.

Filtration System

Filtration systems combine multiple filters and components to provide comprehensive filtration solutions for specific steel manufacturing applications. They include pre-filters, main filters, and post-filters to remove various types and sizes of contaminants.

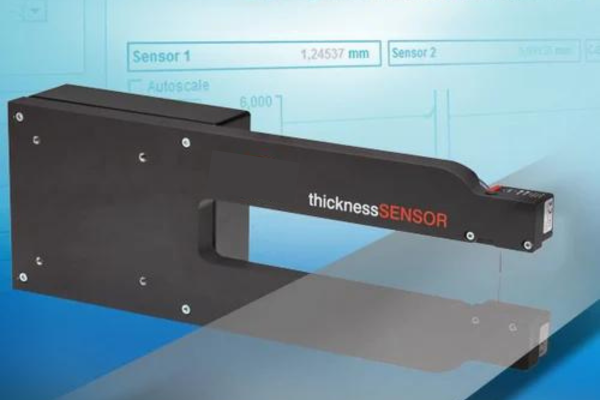

Thickness Sensors

Thickness sensors are used to measure and monitor the thickness of steel sheets, plates, and other materials during production processes. They ensure the accuracy and uniformity of thickness for quality control and compliance with specifications.

Gas and Chemical Sensors

Gas and chemical sensors are utilized to detect and monitor the presence and concentration of gases, such as oxygen, carbon dioxide, and harmful fumes in the steel manufacturing environment. They help maintain safe working conditions and ensure compliance with environmental regulations.

Applications of Filters and Filtration Systems

Cooling Systems

Filters and filtration systems are used in cooling systems to remove debris, rust particles, and impurities from water or coolant. They protect heat exchangers, pumps, and nozzles from clogging, ensuring efficient heat transfer and maintaining optimal cooling performance.

Hydraulic Systems

Filters are essential components in hydraulic systems to remove contaminants, such as dirt, metal particles, and debris, from hydraulic fluids. They prevent damage to hydraulic pumps, valves, and actuators, maintaining smooth and reliable operation.

Lubrication Systems

Filters and filtration systems are employed in lubrication systems to eliminate contaminants and maintain clean lubricating oil. They enhance the performance and lifespan of bearings, gears, and other components by reducing friction and wear.

Compressed Air Systems

Air filters and filtration systems ensure the purity and quality of compressed air used in pneumatic systems, air-operated tools, and control valves. They protect sensitive pneumatic components from contamination, ensuring reliable and efficient operation.

Gas Supply Systems

Filters and filtration systems are utilized in gas supply systems to remove impurities and contaminants from gases such as oxygen, nitrogen, and argon. They ensure the purity of gases used in processes such as gas cutting, gas shielding, and heat treatment, preventing equipment damage and ensuring product quality.

Water Treatment

Filters and filtration systems play a vital role in water treatment processes in the steel industry. They remove sediment, suspended solids, and impurities from water used in cooling systems, quenching operations, and other applications.

Dust and Emission Control

Bag filters and other filtration systems are employed in steel manufacturing plants to control dust emissions and maintain a clean working environment. They capture and collect dust particles from exhaust gases, preventing their release into the atmosphere and ensuring compliance with environmental regulations.

Process Water Filtration

Filtration systems are used to treat process water in steel manufacturing, ensuring its cleanliness and suitability for various applications. They remove suspended solids, organic matter, and contaminants from process water, reducing equipment fouling and maintaining process efficiency.

Scale and Sludge Removal

Filters and filtration systems are employed for the removal of scale and sludge from process fluids in steel manufacturing. They capture and separate solid particles and impurities, preventing their deposition on equipment surfaces and reducing maintenance requirements.

Waste Water Treatment

Filtration systems are utilized in waste water treatment processes to remove pollutants, solids, and impurities from wastewater generated in steel manufacturing. They play a crucial role in ensuring compliance with environmental regulations and minimizing the environmental impact of steel production.

Paint Booth Filtration

Filters and filtration systems are used in paint booths and spray booths to capture overspray particles and prevent their release into the environment. They improve paint booth air quality, protect equipment, and ensure high-quality paint finishes.

Key Features and Benefits

Equipment Protection

Filters and filtration systems protect equipment and components from damage caused by contaminants, extending their lifespan and reducing maintenance costs.

Product Quality

Effective filtration ensures the purity and cleanliness of fluids and gases, improving product quality and consistency in steel manufacturing processes.

Operational Efficiency

Clean fluids and gases obtained through filtration systems enhance the efficiency and performance of equipment, resulting in improved operational efficiency.

Environmental Compliance

Filters and filtration systems help steel manufacturers meet environmental regulations by capturing and removing contaminants, reducing emissions, and preventing pollution.

Worker Safety

Filtration systems improve air quality and create a clean working environment, promoting worker safety and reducing the risk of respiratory issues.

Cost Savings

By preventing equipment damage, reducing maintenance requirements, and improving process efficiency, filters and filtration systems contribute to cost savings in steel manufacturing operations.

In summary, filters and filtration systems are essential components in the steel manufacturing industry. They remove impurities, contaminants, and particulate matter from fluids, gases, and exhaust streams, ensuring equipment protection, product quality, and operational efficiency. These systems find applications in cooling systems, hydraulic systems, lubrication systems, compressed air systems, gas supply systems, water treatment, dust and emission control, and more. Filters and filtration systems provide benefits such as equipment protection, improved product quality, operational efficiency, environmental compliance, worker safety, and cost savings.