Rolling Mill Stands

Our range of rolling mill stands is engineered to meet the demanding requirements of the steel manufacturing industry, ensuring efficient and accurate rolling operations.

- Home

- Products

- Rolling Mill Solutions

- Rolling Mill Stands

Our Products

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. or just call us now.

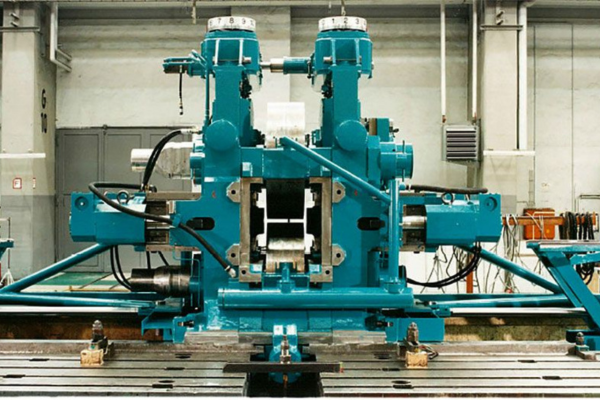

Rolling Mill Stands Overview

Rolling mill stands are crucial components in the rolling mill process, designed to support and guide the rolling operation of metal materials. They provide stability, strength, and precision during the shaping and deformation of metal into various forms, such as sheets, bars, or structural sections. Our range of rolling mill stands is engineered to meet the demanding requirements of the steel manufacturing industry, ensuring efficient and accurate rolling operations.

Range of Rolling Mill Stands

Cantilever Mill Stands

Cantilever mill stands consist of a single column and support the rolling process from one side.

They are used for light to medium-duty applications and provide easy access for maintenance and roll changes.

Housingless mill stands feature a compact design without traditional housings, allowing for better access and visibility during operation.

They are suitable for heavy-duty applications and provide increased rigidity and stability for precise and high-speed rolling.

Housingless Mill Stands

Double Housing Mill Stands

Double housing mill stands have two separate housings that enclose the rolls on both sides.

They provide enhanced strength, stability, and load-bearing capacity, making them suitable for heavy-duty rolling processes.

Universal mill stands are versatile stands that can be adjusted to accommodate various roll sizes and configurations.

They offer flexibility in rolling different types and sizes of metal products, providing efficient and adaptable rolling solutions.

Universal Mill

Stands

Key Features and Benefits

Robust Construction

Our rolling mill stands are built with high-quality materials and robust construction to withstand the heavy loads and stresses of the rolling process. They provide the necessary strength and stability to maintain precise alignment and ensure accurate shaping of the metal.

Roll Alignment and Adjustment

Rolling mill stands are designed with mechanisms for easy roll alignment and adjustment. This allows operators to precisely position the rolls, ensuring proper contact and distribution of forces during the rolling process.

Roll Cooling and Lubrication

Some rolling mill stands are equipped with integrated roll cooling and lubrication systems. This ensures effective heat dissipation, prolongs the life of the rolls, and maintains the desired temperature during rolling operations.

Pass Line Adjustment

Rolling mill stands feature pass line adjustment mechanisms that allow operators to control the entry and exit angles of the metal material during rolling. This ensures consistent and accurate shaping of the metal and facilitates the production of precise dimensions and profiles.

Accessibility and Maintenance

Our rolling mill stands are designed with easy access for maintenance and roll changes. This reduces downtime, enhances operational efficiency, and enables quick and convenient maintenance and repair tasks.

Application

Hot Rolling Mills

Rolling mill stands are extensively used in hot rolling mills for shaping steel slabs, billets, or blooms into various forms, such as plates, sheets, rods, or profiles. They provide the necessary stability, alignment, and control to achieve precise dimensions and desired mechanical properties.

Cold Rolling Mills

In cold rolling mills, rolling mill stands are employed to reduce the thickness of steel sheets or strips while maintaining uniform thickness and surface quality. They ensure accurate and consistent reduction in thickness, achieving the desired final dimensions and surface finish.

Structural Rolling Mills

Rolling mill stands find application in structural rolling mills that produce steel sections, such as I-beams, H-beams, channels, and angles. They enable the precise shaping and deformation of steel sections, ensuring the desired dimensions and structural properties.

Wire and Rod Mills

Rolling mill stands are used in wire and rod mills for shaping steel wires and rods into various sizes and profiles. They ensure the accurate and uniform reduction of the wire or rod diameter, producing high-quality finished products for applications in construction, automotive, and manufacturing industries.

TMT Rolling Mills

Rolling mill stands play a crucial role in TMT rolling mills, where the steel billets are subjected to a series of rolling and heat treatment processes. They provide the necessary support and control to achieve controlled deformation, temperature, and cooling rates, resulting in the desired microstructure and mechanical properties of the TMT bars.

Specialized Rolling Mills

Rolling mill stands are utilized in specialized rolling mills that produce specific steel products, such as seamless tubes, railway tracks, or automotive components. They are tailored to meet the unique requirements of these applications, ensuring precise shaping and dimensional accuracy.

In summary, our range of rolling mill stands offers robust construction, precise alignment, and adjustable features to support various rolling processes in the steel manufacturing industry. Whether used in hot rolling mills, cold rolling mills, structural rolling mills, wire and rod mills, TMT rolling mills, specialized rolling mills, or research and development facilities, our rolling mill stands ensure efficient and accurate shaping of metal materials. We continuously strive to innovate and improve our rolling mill stands, incorporating the latest technologies to meet the evolving needs and challenges of the steel industry.