Reheating Furnaces

Our range of reheating furnaces is engineered to provide efficient and uniform heating, ensuring the proper plasticity and workability of the steel during the rolling process.

- Home

- Products

- Rolling Mill Solutions

- Reheating Furnaces

Our Products

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. or just call us now.

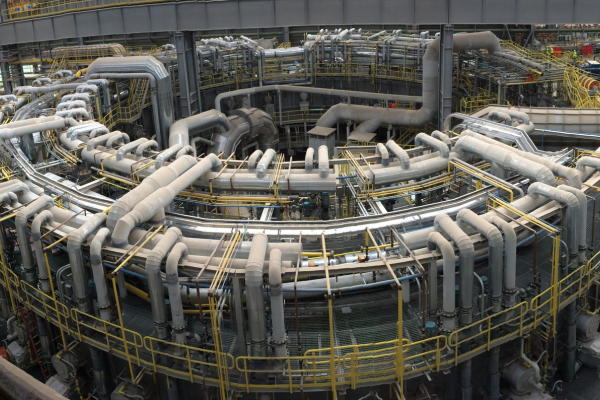

Reheating Furnaces Overview

Reheating furnaces are essential equipment in the steel manufacturing industry, specifically in the hot rolling process. These furnaces are designed to reheat steel slabs, billets, or blooms to the optimal temperature required for subsequent rolling operations. Our range of reheating furnaces is engineered to provide efficient and uniform heating, ensuring the proper plasticity and workability of the steel during the rolling process.

Range of Reheating Furnaces

Pusher Type Reheating Furnaces

Pusher type reheating furnaces feature a pusher mechanism that moves the steel billets or slabs through the furnace on a series of refractory skids.

They are suitable for continuous and high-volume production, ensuring rapid and uniform heating of the steel.

Walking beam reheating furnaces utilize a walking beam mechanism to transport the steel billets or slabs through the furnace.

They provide gentle and precise handling of the steel, ensuring uniform heating and minimizing surface damage or deformation.

Walking Beam Reheating Furnaces

Rotary Hearth Reheating Furnaces

Rotary hearth reheating furnaces employ a rotating hearth to transport the steel material through the heating chamber.

They offer flexibility in accommodating various sizes and shapes of steel products, making them suitable for a wide range of applications.

Batch type reheating furnaces are designed to handle smaller quantities of steel at a time.

They are versatile and can be used for reheating different steel products, such as bars, plates, or blooms.

Batch Type Reheating Furnaces

Key Features and Benefits

Efficient Heating

Reheating furnaces are equipped with advanced combustion systems, insulation materials, and control mechanisms to ensure efficient heat transfer and energy utilization. They provide rapid and uniform heating, reducing cycle times and optimizing production efficiency.

Temperature Control

Our reheating furnaces feature precise temperature control systems that enable operators to set and maintain the desired heating temperature for different steel grades and product specifications. This ensures consistent and controlled heating, resulting in the desired material properties during the subsequent rolling process.

Uniform Heating

The design of our reheating furnaces, coupled with advanced combustion technology and heat distribution systems, ensures uniform heating of the steel material. This minimizes temperature variations across the steel product, promoting even plasticity and workability during rolling operations.

Reduced Scale Formation

Reheating furnaces are equipped with scale prevention measures, such as protective atmospheres or coatings, to minimize scale formation on the steel surface during the heating process. This helps maintain the cleanliness of the steel, reducing surface defects and improving the quality of the rolled products.

Automation and Safety

Our reheating furnaces are equipped with advanced automation and safety features, including temperature monitoring, flame detection, and interlock systems. These features ensure reliable and safe operation, protecting both the equipment and personnel involved in the heating process.

Application

Hot Rolling Mills

Reheating furnaces are integral components of hot rolling mills, where they are used to reheat steel slabs, billets, or blooms prior to the rolling process. They provide the necessary temperature and plasticity required for shaping the steel into various forms, such as plates, sheets, or structural sections.

Metal Fabrication

In metal fabrication operations, reheating furnaces are utilized to heat steel materials prior to bending, shaping, or welding. By providing controlled and precise heating, they enhance the formability and workability of the steel, facilitating the fabrication processes.

Steel Forging

Reheating furnaces are also used in steel forging processes, where they are responsible for heating the steel billets or ingots to the appropriate temperature for forging. By providing uniform and controlled heating, they ensure that the steel is malleable and ready for shaping and forming into the desired forged products.

Heat Treatment Facilities

Reheating furnaces find application in heat treatment facilities, where they are used for preheating steel components before undergoing processes such as annealing, quenching, or tempering. They enable the steel to reach the required temperature range for the subsequent heat treatment, ensuring the desired material properties are achieved.

Steel Service Centers

Steel service centers utilize reheating furnaces to process and heat steel materials for various downstream applications. They enable the customization and preparation of steel products according to customer requirements, ensuring optimal material properties for subsequent use.

Research and Development

Reheating furnaces are employed in research and development facilities to study the behavior of different steel grades and alloys under specific heating conditions. They allow researchers to simulate industrial heating processes and evaluate the material properties and performance of the steel under various temperature profiles.

In summary, our range of reheating furnaces offers efficient and precise heating solutions for a variety of applications in the steel manufacturing industry. Whether used in hot rolling mills, steel service centers, forging operations, heat treatment facilities, metal fabrication, research, or specialized steel production, our reheating furnaces provide reliable and uniform heating, enabling the production of high-quality steel products. We continuously strive to innovate and customize our furnaces to meet the unique needs and requirements of our customers, ensuring optimal performance and customer satisfaction.