Quality Assurance Equipment

Our range of quality assurance equipment includes advanced tools and instruments that enable accurate measurement, testing, and analysis of various parameters.

- Home

- Products

- Rolling Mill Solutions

- Quality Assurance Equipment

Our Products

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. or just call us now.

Quality Assurance Equipment Overview

Quality assurance equipment plays a vital role in the steel manufacturing industry by ensuring the production of high-quality products that meet the required specifications and standards. Our range of quality assurance equipment includes advanced tools and instruments that enable accurate measurement, testing, and analysis of various parameters, allowing for effective quality control and process optimization.

Key Types of Quality Assurance Equipment

Dimensional Measurement Tools

Dimensional measurement tools, such as calipers, micrometers, and laser measurement systems, are used to measure the dimensions and tolerances of steel products. They provide precise and reliable measurements, ensuring compliance with dimensional specifications and facilitating quality control.

Hardness Testers

Hardness testers measure the hardness or resistance of steel products to deformation or penetration. Techniques such as Rockwell, Brinell, and Vickers hardness testing provide valuable information about the material's mechanical properties and its suitability for specific applications.

Spectroscopy and Chemical Analysis Equipment

Spectroscopy and chemical analysis equipment, such as spectrometers and analyzers, are used to determine the chemical composition of steel materials. They help ensure the proper composition of alloys, identify impurities, and verify compliance with industry standards and customer requirements.

Non-Destructive Testing (NDT) Equipment

NDT equipment utilizes methods that do not damage or permanently alter the integrity of the tested materials. Techniques such as ultrasonic testing, magnetic particle inspection, and radiographic testing are used to detect defects, cracks, or abnormalities in steel products without causing any harm.

Application

Incoming Raw Material Inspection

Quality assurance equipment is used to inspect and verify the quality of incoming raw materials, such as steel billets or coils. This ensures that the materials meet the required specifications and standards before being used in the manufacturing process.

In-Process Quality Control

Quality assurance equipment is employed at various stages of the manufacturing process to monitor and control critical parameters. It helps identify deviations, defects, or abnormalities, allowing for immediate corrective measures and process optimization.

Final Product Inspection

Quality assurance equipment is utilized for the final inspection of steel products before they are released for shipment. This ensures that the products meet the required quality standards, specifications, and customer expectations.

Quality Management and Continuous Improvement

Quality assurance equipment is instrumental in establishing and maintaining quality management systems. It provides data and feedback that enable data-driven decision-making, process improvement, and the implementation of corrective and preventive actions.

Benefits of Quality Assurance Equipment

Compliance with Standards and Specifications

Quality assurance equipment ensures that steel products meet the required industry standards, specifications, and customer expectations.

Enhanced Product Quality and Reliability

By detecting defects, abnormalities, or variations, quality assurance equipment helps eliminate substandard products, ensuring consistent quality and reliability.

Process Optimization

The data and insights provided by quality assurance equipment enable process optimization, reducing waste, improving efficiency, and enhancing overall productivity.

Customer Satisfaction and Market Reputation

Delivering high-quality products through effective quality assurance enhances customer satisfaction and builds a positive market reputation.

Cost Reduction

Early detection of defects and deviations through quality assurance equipment helps avoid costly rework, scrap, or customer rejections, resulting in cost savings.

In addition to the aforementioned types of quality assurance equipment, there are several other tools and instruments used in the steel manufacturing industry for quality control. These include:

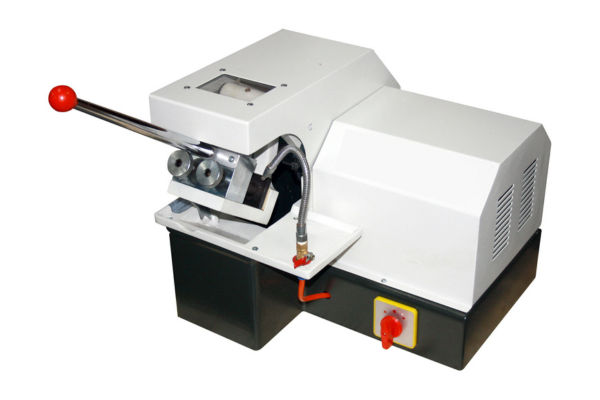

Tensile Testing Machines

Tensile testing machines measure the tensile strength and elongation properties of steel materials. They apply controlled tension to a sample until it breaks, providing valuable information about its mechanical behavior and structural integrity.

Impact Testing Machines

Impact testing machines evaluate the toughness and resistance of steel materials to sudden loading or impact. They measure the energy absorbed by a sample when struck by a pendulum or other impact mechanism, helping assess its ability to withstand dynamic loading conditions.

Corrosion Testing Equipment

Corrosion testing equipment assesses the corrosion resistance of steel products under various environmental conditions. Techniques such as salt spray testing, electrochemical testing, and humidity chambers help determine the material's susceptibility to corrosion and aid in the development of corrosion protection measures.

Coating Thickness Gauges

Coating thickness gauges measure the thickness of protective coatings applied to steel surfaces. They ensure that coatings, such as paint or galvanized layers, meet the required specifications, providing corrosion protection and aesthetic appeal.

Metallographic Equipment

Metallographic equipment, including optical microscopes and sample preparation tools, is used to analyze the microstructure of steel materials. It allows for the examination of grain size, inclusion content, and other microstructural features, providing insights into the material's properties and manufacturing processes.

Ultrasonic Thickness Gauges

Ultrasonic thickness gauges use ultrasonic waves to measure the thickness of steel plates, pipes, and other components. They are used for routine inspections, ensuring that the material meets the specified thickness requirements and identifying areas of potential thinning or corrosion.

These quality assurance equipment are utilized throughout the steel manufacturing process to ensure the production of high-quality products, minimize defects, and meet the stringent requirements of customers and industry standards. By employing these tools, manufacturers can optimize their processes, enhance product performance and reliability, and maintain a competitive edge in the market.