Slide Gate Plate and Nozzle

Home » Our Products » Spares and Consumables » Slide Gate Plate and Nozzle

our products

Slide Gate Plate and Nozzle

get in touch

At Infinity Steel Industries Resources, we are committed to providing seamless communication and exceptional customer service. Whether you have questions about our products, need technical assistance, or are interested in exploring how we can support your steel manufacturing needs, our team is ready to assist you.

product category

High-Performance Slide Gate Plates and Nozzles for Steel Casting

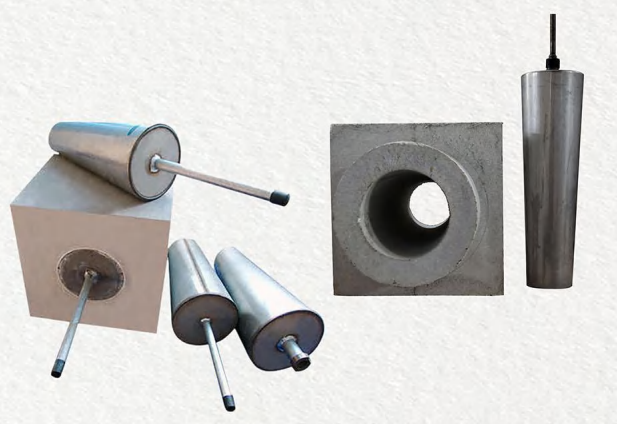

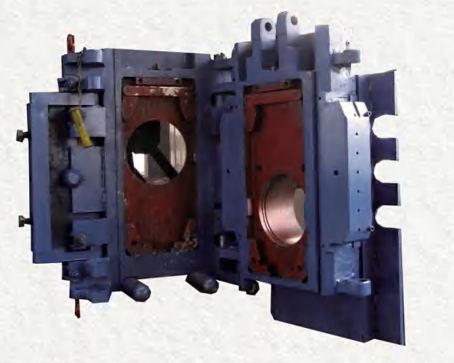

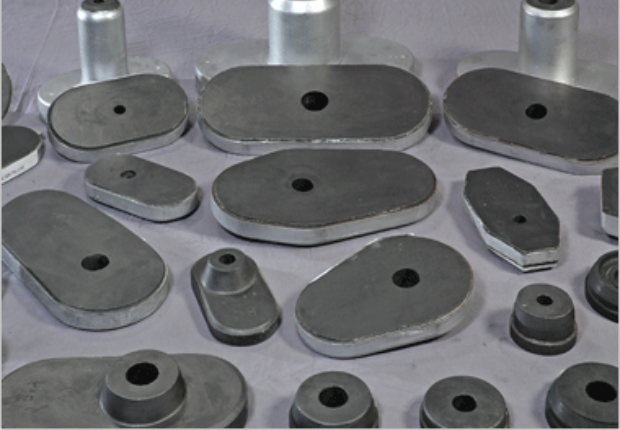

Converter Slide Gate Plate

The slide gate plate is made of sintered corundum, fused corundum, fused zirconium corundum, zirconium mullite and other main raw materials. It is combined with new resin, formed by high pressure and fired at high temperature. It has the advantages of high strength, super hard, high temperature resistance and corrosion resistance, and strong thermal stability.

| Item | Zro, material | Al-C material |

|---|---|---|

| ZrO2+Al2O3% | ≥90 | --- |

| Al2O3% | --- | ≥75 |

| C% | ≤1 | ≤5 |

| B.D g/cm³ | ≥3.20 | ≥3.10 |

| AP. % | ≤4 | ≤4 |

| Cold Bending Strength MPa | ≥25 | ≥25 |

| CCS MPa | ≥180 | ≥180 |

Converter Nozzle

This product is made of high quality fused magnesia and flake graphite as the main raw materials, adding a vari-ety of anti-oxidant and additives, high pressure molding, with high density, high strength, corrosion resistance, erosion resistance, peeling resistance, long life characteristics, easy to install, easy to replace.

| Item | Alumina-mullite material | Al-C material |

|---|---|---|

| SiO2+Al2O3% | ≥90 | --- |

| A1203% | --- | ≥88 |

| C% | ≥6 | ≤7 |

| B.D g/cm³ | ≥3.05 | ≥3.10 |

| AP. % | ≥8 | ≤8 |

| CCS MPa | ≥120 | ≥120 |

- Features :

- Durability and Longevity

- Precision Flow Control

- Cost-Efficiency

- High Thermal Resistance

- Easy Installation and Maintenance

- Conclusion:

Infinity Steel Industries Resources provides high-quality Slide Gate Plates and Nozzles that play a vital role in controlling and directing the flow of molten metal during the steel casting process. Crafted from advanced, high-performance refractory materials, these components ensure precise flow control, superior durability, and resistance to extreme conditions, such as high temperatures and thermal shock.