Rolling Mill Rolls

Home » Our Products » Rolling Mill Solutions » Rolling Mill Rolls

our products

Rolling Mill Rolls

get in touch

At Infinity Steel Industries Resources, we are committed to providing seamless communication and exceptional customer service. Whether you have questions about our products, need technical assistance, or are interested in exploring how we can support your steel manufacturing needs, our team is ready to assist you.

High-Performance Rolling Mill Rolls for Maximum Efficiency

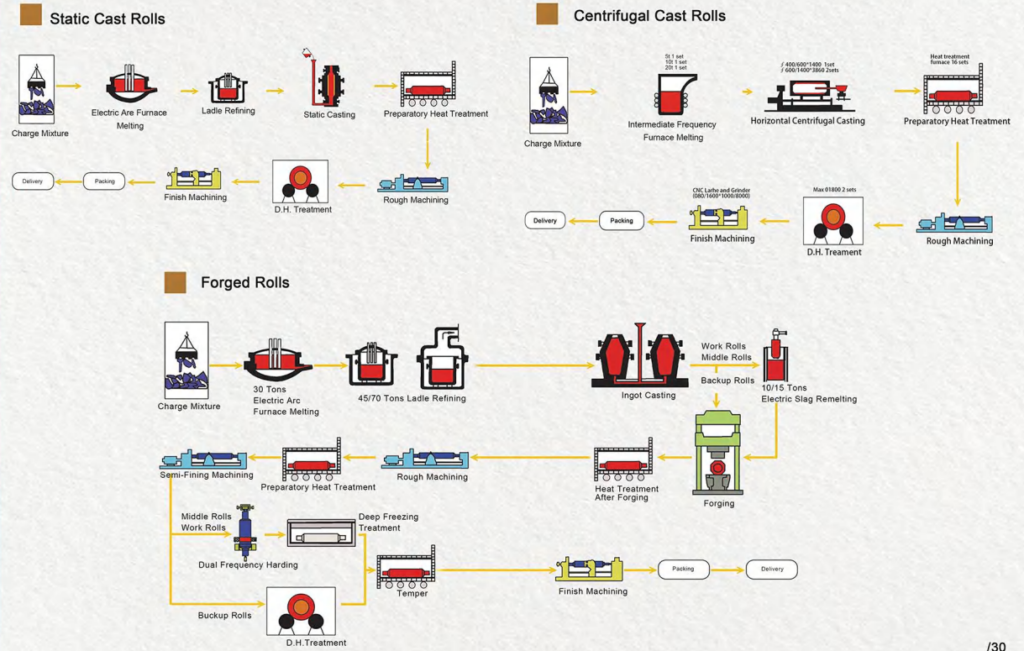

All the melting furnaces are automatical-ly controlled by PLC with very good working conditions, they are equipped with automatic alarm system and fur-nished with perfect equipment for elimi nating smoke and dust. All the raw ma-terials for smelting are strictly controlled, the chemical composition are precisely tested to ensure the qualified melting process. Thereby, the refining process shows also excellent resuits.

The company possesses 8 melting facilities, including an Electric Arc Furnace for steel melting of 30tons, 45/70tons LF-VD Furnaces, Electric Slag Remelting Furnaces (10tons and 15tons), and medium frequency Induction Melting Furnaces (Stons, 10tons and20tons). These melting facilities in total can accomplish a daily smelting capacity of 120tons molten steel, 240tons of molten iron and 25tons of electric slag remelting.

1.Heat Treatment Equipment

– There are sixteen sets of car-type electric resis-tance furnaces and gas furnaces operating with high, medium and low temperature, two sets of dif-ferential heat treatment furnaces, one set of dual frequency induction quenching machine, two sets of spray quenching machines, one set of high-fre-quency hardening machine and two sets of deep freezing treatment troughs. All the furnaces are computer controlled, with the furnace temperature deviation less than 10 degree, which ensures very good uniformity of roll hardness.

– LMM GROUP has two sets of horizontal centrifugal casting machines, with the maximum centrifugal cast roll size of Dia. 1400x3860mm Barrel Length. The centrifugal casting machines can realize the integration of spray coating and controlling the mould temperature. They are driven by hydraulic motor and operated steadily. The speed of rotation could reach 1500r/min, which can assure the technical requirement on gravity multiple accurately and confirm the best quality of work-ing layer.

2. Forging Equipment

– There is one set of 45MN Oil Hydraulic Press which can ensure the adequate ratio of forging reduction and deformation for forged rolls.

3. Testing Equipment

– The company has the most advanced inspection and testing equipments such as X-ray Fluorescence Spectrometer, Plasma Emission Spectrometer, Optical Emission Spec-trometer(OBLF), Hydrogen/Oxgen/Nitrogen Combined Analyzer (LECO), Carbon/Sulfur Analyzer for chemical analysis, and also has Scanning Electron Microscope, Metalo-scope, Image Analyzer (Zeiss), Microhardness Tester, Universal Testing Machine, Impact Testing Machine, Analog and Digital Ultrasonic Testing Device, Magnetic Powder UT Tester, Stress Meter, Portable Leeb & Shore Hardness Tester, etc. All these instruments and equipments can guarantee the Quality Assurance effectively.

Machining Equipment

– There are 36sets of machining equipment, including CNC lathes, CNC grind-ers, and CNC double-sided milling machines. The machining range can be dia 80×1000-dia 1600x8000mm and precision ranges up to 0.003mm.

- For Cold Strip Mill

- Chemical Composition

| Grade | C | Si | Mn | Ni | Cr | Mo |

| Cr3 | 0.6-1.0 | 0.3-0.6 | 0.2-0.5 | 0-0.8 | 2.5-3.5 | 0.2-0.5 |

| Cr5 | 0.5-0.9 | 0.3-0.8 | 0.2-0.5 | 0-0.8 | 4.5-5.5 | 0.2-0.8 |

- Physical Properties

| Grade | Barrel Hardness | Neck Hardness | Tensile Strength |

| Shore D | Shore D | Mpa | |

| Cr3 | Work Roll: 90-100 | 35-50 | ≥950 |

| Intermediate Roll: 75-85 | |||

| Cr5 | Work Roll: 90-100 | 35-50 | ≥1050 |

| Intermediate Roll: 75-85 |

- For Hot Strip Mill

- Chemical Composition

| Grade | C | Si | Mn | Ni | Cr | Mo | V | W |

|---|---|---|---|---|---|---|---|---|

| ICDP Roll | 2.9-3.6 | 0.6-1.5 | 0.4-1.2 | 3.01-4.8 | 1.0-2.0 | 0.2-2.0 | 0.2-2.0 | 0.0-2.0 |

| HiCr Iron Roll | 2.3-3.3 | 0.3-1.0 | 0.5-1.2 | 0.7-1.7 | 15.0-18.0 | 0.7-1.5 | 0.0-0.6 | |

| HiCr Steel Roll | 1.0-1.8 | 0,4-1.0 | 0.5-1.0 | 0.5-1.5 | 8.0-15.0 | 1.5-4.5 | ||

| HSS Roll | 1.5-2.2 | 0.3-1.0 | 0.4-1.2 | 0.0-1.5 | 3.0-8.0 | 2.0-8.0 | 2.0-9.0 | 0.0-8.0 |

- Physical Properties

| Grade | Barrel Hardness | Neck Hardness | Tensile Strength |

| Shore D | Shore D | Mpa | |

| ICDP Roll | 70-85 | 35-45 | ≥400 |

| HiCr Iron Roll | 70-85 | 35-45 | ≥500 |

| HiCr Steel Roll | 70-85 | 35-45 | ≥700 |

| HSS Roll | 80-90 | 35-45 | ≥700 |

- For Plate Mill

- Chemical Composition

| Grade | C | Si | Mn | Ni | Cr | Mo | V | W |

|---|---|---|---|---|---|---|---|---|

| ICDP Roll | 2.9-3.6 | 0.6-1.5 | 0.4-1.2 | 3.01-4.8 | 1.0-2.0 | 0.2-1.0 | ||

| HiCr Iron Roll | 2.3-3.3 | 0.3-1.0 | 0.5-1.2 | 0.7-1.7 | 15.0-18.0 | 0.7-1.5 | 0.0-0.6 | |

| HiCr Steel Roll | 1.0-1.8 | 0.4-1.0 | 0.5-1.0 | 0.5-1.5 | 8.0-15.0 | 1.5-4.5 | ||

| HSS Roll | 1.5-2.2 | 0.3-1.0 | 0.4-1.2 | 0.0-1.5 | 3.0-8.0 | 2.0-8.0 | 2.0-9.0 | 0.0-8.0 |

- Physical Properties

| Grade | Barrel Hardness | Neck Hardness | Tensile Strength |

| Shore D | Shore D | Mpa | |

| ICDP Roll | 65-80 | 35-45 | ≥400 |

| HiCr Iron Roll | 65-80 | 35-45 | ≥500 |

| HiCr Steel Roll | 65-80 | 35-45 | ≥700 |

- Alloy indefinite chilled cast iron rolls

- Chemical Analysis

| Designation of rolls | Material code | C | Si | Mn | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| CrMo indefinite chilled cast iron roll | IC | 3.1-3.4 | 0.6-0.9 | 0.5-1.0 | 0.7-1.1 | 0.2-0.6 | |

| NiCrMo indefinite chilled cast iron roll (I) | IC I | 3.1-3.4 | 0.6-0.9 | 0.5-1.0 | 0.6-0.8 | 0.7-1.1 | 0.2-0.6 |

| NiCrMo indefinite chilled cast iron roll (II) | IC II | 3.1-3.4 | 0.6-1.0 | 0.5-1.0 | 2.2-2.8 | 0.7-1.1 | 0.2-0.6 |

| NiCrMo indefinite chilled cast iron roll (III) | IC III | 3.1-3.4 | 0.6-1.0 | 0.5-1.0 | 2.2-2.8 | 0.8-1.3 | 0.2-1.0 |

| NiCrMo indefinite chilled cast iron roll (IV) | IC IV | 3.1-3.4 | 0.6-1.0 | 0.5-1.0 | 3.1-4.3 | 1.0-1.3 | 0.2-1.0 |

| NiCrMo indefinite chilled cast iron roll (V) | IC V | 3.1-3.4 | 0.8-1.2 | 0.5-1.0 | 3.8-4.5 | 1.4-2.0 | 0.2-1.2 |

- Physical Properties

| Designation of rolls | Material code | Barrel hardness (HSD) | Neck hardness (HSD) | Tensile strength (Mpa) |

|---|---|---|---|---|

| CrMo indefinite chilled cast iron roll | IC | 50-70 | 35-55 | >160 |

| NiCrMo indefinite chilled cast iron roll (1) | IC I | 55-72 | 35-55 | >160 |

| NiCrMo indefinite chilled cast iron roll (II) | IC II | 55-72 | 35-55 | >160 |

| NiCrMo indefinite chilled cast iron roll (III) | IC III | 65-78 | 35-55 | >350 |

| NiCrMo indefinite chilled cast iron roll (IV) | IC IV | 70-83 | 35-55 | >350 |

| NiCrMo indefinite chilled cast iron roll (V) | IC V | 77-82 | 35-55 | >350 |

- Microstructure

| Designation of rolls | Material code | Microstructure |

| CrMo indefinite chilled cast iron roll | IC | Pearlite+cementite small percentage graphite |

| NiCrMo indefinite chilled cast iron roll (1) | IC I | Pearlite+cementite+small percentage graphite |

| NiCrMo indefinite chilled cast iron roll (II) | IC II | Fine pearlite cementite+small percentage graphite |

| NiCrMo indefinite chilled cast iron roll (III) | IC III | Sorbite+cementite+small percentage graphite |

| NiCrMo indefinite chilled cast iron roll (IV) | IC IV | Sorbite tempered bainite+carbide+graphite+A small amount of martensite or bainite carbide+graphite |

| NiCrMo indefinite chilled cast iron roll (V) | IC V | Sorbite tempered bainite+carbide+graphite+A small amount of martensite or bainite carbide graphite |

- Application

| Designation of rolls | Material code | Microstructure |

| CrMo indefinite chilled cast iron roll | IC | Pearlite+cementite small percentage graphite |

| NiCrMo indefinite chilled cast iron roll (1) | IC I | Pearlite+cementite+small percentage graphite |

| NiCrMo indefinite chilled cast iron roll (II) | IC II | Fine pearlite cementite+small percentage graphite |

| NiCrMo indefinite chilled cast iron roll (III) | IC III | Sorbite+cementite+small percentage graphite |

| NiCrMo indefinite chilled cast iron roll (IV) | IC IV | Sorbite tempered bainite+carbide+graphite+A small amount of martensite or bainite carbide+graphite |

| NiCrMo indefinite chilled cast iron roll (V) | IC V | Sorbite tempered bainite+carbide+graphite+A small amount of martensite or bainite carbide graphite |

- Alloy chilled cast iron rolls

- Chemical Analysis

| Designation of rolls | Material code | C | S | Mn | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| NiCrMo chilled cast iron rolls (I) | CC I | 3.00-3.40 | 0.30-0.80 | 0.20-1.00 | 0.50-1.00 | 0.20-0.60 | 0.20-0.60 |

| NiCrMo chilled cast iron rolls (II) | CC II | 3.00-3.40 | 0.30-0.80 | 0.20-1.00 | 1.10-2.00 | 0.30-1.20 | 0.20-0.60 |

| NiCrMo chilled cast iron rolls (III) | CC III | 3.00-3.40 | 0.30-0.80 | 0.20-1.00 | 2.10-3.00 | 0.50-1.50 | 0.20-0.60 |

| NiCrMo chilled cast iron rolls (IV) | CC IV | 3.00-3.40 | 0.30-0.80 | 0.20-1.00 | 3.10-4.00 | 0.50-1.70 | 0.20-0.60 |

- Physical Properties

| Designation of rolls | Material code | Barrel hardness (HSD) | Neck hardness (HSD) | Tensile strength (Mpa) |

|---|---|---|---|---|

| NiCrMo chilled cast iron rolls (I) | CC I | 60-70 | 32-50 | >150 |

| NiCrMo chilled cast iron rolls (II) | CC II | 62-75 | 35-52 | >150 |

| NiCrMo chilled cast iron rolls (III) | CC III | 65-80 | 32-45 | >350 |

| NiCrMo chilled cast iron rolls (IV) | CC IV | 70-85 | 32-45 | >350 |

- Microstructure

| Designation of rolls | Material code | Microstructure |

| NiCrMo chilled cast iron rolls (I) | CC I | Pearlite+cementite |

| NiCrMo chilled cast iron rolls (II) | CC II | Fine pearlite+cementite |

| NiCrMo chilled cast iron rolls (III) | CC III | Fine pearlite+cementite |

| NiCrMo chilled cast iron rolls (IV) | CC IV | Sorbite+cementite |

- Application

| Designatian ot rolis | Material code | Application |

| NiCrMo chilled cast iron rolls (I) | CC I | Section mill, bar mill, wire-rod mill narrow strip mill, finishing stand |

| NiCrMo chilled cast iron rolls (II) | CC II | Section mill, bar mill, wire-rod mill narrow strip mill, finishing stand |

| NiCrMo chilled cast iron rolls (III) | CC III | Section mill, bar mill, wire-rod mill narrow strip mill, finishing stand |

| NiCrMo chilled cast iron rolls (IV) | CC IV | Section mill, bar mill, wire-rod mill narrow strip mill, finishing stand |

- Alloy SG rolls

- Chemical Analysis

| Designation of rolls | Material code | C | Si | Mn | Ni | Cr | Mo | Mg |

|---|---|---|---|---|---|---|---|---|

| CrMo indefinite chilled SG cast iron rolls | SG II | 3.00-3.40 | 1.40-1.90 | 0.20-0.80 | 0.20-0.60 | 0.20-0.60 | ≥0.04 | |

| NiCrMo indefinite chilled SG cast iron rolls (I) | SG IV | 3.00-3.40 | 1.40-1.90 | 0.40-0.80 | 0.50-1.00 | 0.20-0.60 | 0.20-0.60 | ≥0.04 |

| NiCrMo indefinite chilled SG cast iron rolls (II) | SG V | 3.00-3.40 | 1.40-1.90 | 0.40-0.80 | 1.10-2.00 | 0.30-1.00 | 0.20-0.60 | ≥0.04 |

- Physical Properties

| Designation of rolls | Material code | Barel hardness (HSD) | Neck hardness (HSD) | Tensile strength (Mpa) |

|---|---|---|---|---|

| CrMo indefinite chilled SG cast iron rolls | SG II | 50-70 | 35-55 | >320 |

| NiCrMo indefinite chilled SG cast iron rolls (I) | SG IV | 50-70 | 35-55 | >320 |

| NiCrMo indefinite chilled SG cast iron rolls (II) | SG V | 60-70 | 35-55 | >320 |

- Microstructure

| Designation of rolis | Material code | Microstructure |

| CrMo indefinite chilled SG cast iron rolls | SG II | Pearlite+cementite+small Graphite |

| NiCrMo indefinite chilled SG cast iron rolls (I) | SG IV | Pearlite+cementite+small Graphite |

| NiCrMo indefinite chilled SG cast iron rolls (II) | SG V | Fine pearlite+cementite+small Graphite |

- Application

| Designatian of rolls. | Material code | Application |

| CrMo indefinite chilled SG cast iron rolls | SG II | Profile, rod, wire and narrow strip mill thick in the rolling mill stand |

| NiCrMo indefinite chilled SG cast iron rolls (I) | SG IV | Profie, rod, wire and narrow strip mill thick in the rolling mill stand |

| NiCrMo indefinite chilled SG cast iron rolls (II) | SG V | Profile, rod, wire and narrow strip mill thick in the roling mill stand |

- Pearlitic ductile cast iron rolls

- Chemical Analysis

| Designation of rolis | Material code | C | S | Mn | Ni | Cr | Mo | Mg |

|---|---|---|---|---|---|---|---|---|

| Pearlitic ductile cast iron roll (I) | SGP I | 3.00-3.40 | 1.40-1.90 | 0.40-0.80 | 1.50-2.00 | 0.20-0.60 | 0.20-0.60 | ≥0.04 |

| Pearlitic ductile cast iron roll (II) | SGP II | 3.00-3.40 | 1.20-2.00 | 0.40-0.80 | 2.01-2.50 | 0.20-1.00 | 0.20-0.60 | ≥0.04 |

| Pearlitic ductile cast iron roll (III) | SGP III | 3.00-3.40 | 1.00-2.00 | 0.40-0.80 | 2.51-3.00 | 0.20-1.20 | 0.20-0.60 | ≥0.04 |

- Physical Properties

| Designation of rolis | Material code | Barrel hardness (HSD) | Neck hardness (HSD) | Tensile strength (Mpa) |

|---|---|---|---|---|

| Pearlitic ductile cast iron roll (I) | SGP I | 45-55 | 35-55 | >450 |

| Pearlitic ductile cast iron roll (II) | SGP II | 55-65 | 35-55 | >450 |

| Pearlitic ductile cast iron roll (III) | SGP III | 62-72 | 35-55 | >450 |

- Microstructurs

| Designation of rolis | Material code | Microstructure |

|---|---|---|

| Pearlitic ductile cast iron roll (I) | SGP I | Pearlite cementite small Graphite |

| Pearlitic ductile cast iron roll (II) | SGP II | Pearlite cementite+small Graphite |

| Pearlitic ductile cast iron roll (III) | SGP III | Globular pearlite+carbide+graphite or a small amount of pearlite+bainite+carbide+spherical graphite |

- Application

| Designation of rolis | Material code | Application |

| Pearlitic ductile cast iron roll (I) | SGP I | Profile, rod, wire and narrow strip mill thick in the roling mill stand |

| Pearlitic ductile cast iron roll (II) | SGP II | Profile, rod, wire and narrow strip mill thick in the roling mill stand |

| Pearlitic ductile cast iron roll (III) | SGP III | Profile, rod, wire and narrow strip mill thick in the roling mill stand |

- Bainite ductile cast iron rolls

- Chemical Analysis

| Designation of rolls | Material code | C | SI | Mn | Ni | Cr | Mo | Mo |

|---|---|---|---|---|---|---|---|---|

| Bainite ductile cast iron roll Centrifugal (I) | SGA I | 3.00-3.40 | 1.20-2.20 | 0.40-0.80 | 3.01-3.50 | 0.20-0.80 | 0.50-1.00 | ≥0.04 |

| Bainite ductile cast iron roll Centrifugal (II) | SGA II | 3.00-3.40 | 1.00-2.00 | 0.40-0.80 | 3.51-4.50 | 0.20-1.00 | 0.50-1.00 | ≥0.04 |

- Physical Properties

| Designation of rolls | Material code | Barrel hardhess (HSD) | Neck hardness (HSD) | Tensile strength (Mpa) |

|---|---|---|---|---|

| Bainite ductile cast iron roll Centrifugal (I) | SGA I | 55-78 | 32-45 | >350 |

| Bainite ductile cast iron roll Centrifugal (II) | SGA II | 60-80 | 32-45 | >350 |

- Microstructurs

| Designation of rolls | Material code | Microstructure |

| Bainite ductile cast iron roll Centrifugal (I) | SGA I | Bainite A small amount of martensite+Carbide graphite |

| Bainite ductile cast iron roll Centrifugal (II) | SGA II | Bainite+A small amount of martensite+Carbide+graphite |

- Application

| Designation of rolls | Material code | Application |

| Bainite ductile cast iron roll Centrifugal (I) | SGA I | Beam, bar, wire rod mill rough rolling, the rolling, pre-finishing mill stand; seamless steel pipe mill reducing rack set |

| Bainite ductile cast iron roll Centrifugal (II) | SGA II | Beam, bar, wire rod mill rough rolling, the rolling, pre-finishing mill stand; seamless steel pipe mill reducing rack set |

- Centrifugal cast iron rolls

- Chemical Analysis

| Designation of rolls | Material code | C | Si | Mn | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| Centrifugal cast iron roll I | HCr I | 3.00-3.30 | 0.30-1.00 | 0.50-1.20 | 0.70-1.70 | 12.00-15.00 | 0.70-1.50 |

| Centrifugal cast iron roll II | HCr II | 3.00-3.30 | 0.30-1.00 | 0.50-1.20 | 0.70-1.70 | 15.01-18.00 | 0.70-1.50 |

| Centrifugal cast iron roll III | HCr III | 3.00-3.30 | 0.30-1.00 | 0.50-1.20 | 0.70-1.70 | 18.01-22.00 | 1.51-3.00 |

- Physical Properties

| Designation of rolls | Material code | Barrel hardness (HSD) | Neck hardhess(HSD) | Tensile strength(HSD) |

|---|---|---|---|---|

| Centrifugal cast iron roll I | HCr I | 60-75 | 32-45 | >350 |

| Centrifugal cast iron roll II | HCr II | 65-80 | 32-45 | >350 |

| Centrifugal cast iron roll III | HCr III | 75-90 | 32-45 | >350 |

- Microstructurs

| Designation of rolls | Material code | Microstructure |

| Centrifugal cast iron roll I | HCr I | Bainite+carbide |

| Centrifugal cast iron roll Il | HCr II | Bainite+carbide |

| Centrifugal cast iron roll III | HCr III | A small amount of bainite+martensite+carbide |

- Application

| Designation of rolls | Material code | Application |

| Centrifugal cast iron roll I | HCr I | Beam, bar, wire rod mill finishing stand; Tropical rough rolling androlling and finishing work roll front; Wide plate mill work roll; |

| Centrifugal cast iron roll II | HCr II | Beam, bar, wire rod mill finishing stand; Tropical rough rolling androlling and finishing work roll front; Wide plate mill work roll; |

| Centrifugal cast iron roll III | HCr III | Beam, bar, wire rod mill finishing stand; Tropical rough rolling androlling and finishina work roll front: Wide plate mill work roll: |

- Alloy cast steel rolls

- Chemical Analysis

| Designation of rolls | Material code | Barrel hardness (HSD) | Neck hardness (HSD) | Tensile strength (Mpa) |

|---|---|---|---|---|

| Zu60CMoMn | AS60 | 35-50 | ≤45 | >650 |

| Zu60CrMoMnNi | AS60 I | 35-45 | ≤45 | >750 |

| Zu65CrNiMo | AS65 I | 35-45 | ≤45 | >750 |

| Zu70Mn | AS70 | 32-42 | ≤45 | >650 |

| Zu70Mn2 | AS70 I | 35-45 | ≤45 | >680 |

| Zu70Mn2Mo | AS70 II | 35-45 | ≤45 | >700 |

| Zu75CrMo | AS75 | 35-50 | ≤45 | >700 |

| Zu75CrNiMnMo | AS75 I | 35-50 | ≤45 | >800 |

- Physical Properties

| Designation of rolls | Material code | Barrel hardness (HSD) | Neck hardness (HSD) | Tensile strength (Mpa) |

|---|---|---|---|---|

| Zu60CMoMn | AS60 | 35-50 | ≤45 | >650 |

| Zu60CrMoMnNi | AS60 I | 35-45 | ≤45 | >750 |

| Zu65CrNiMo | AS65 I | 35-45 | ≤45 | >750 |

| Zu70Mn | AS70 | 32-42 | ≤45 | >650 |

| Zu70Mn2 | AS70 I | 35-45 | ≤45 | >680 |

| Zu70Mn2Mo | AS70 II | 35-45 | ≤45 | >700 |

| Zu75CrMo | AS75 | 35-50 | ≤45 | >700 |

| Zu75CrNiMnMo | AS75 I | 35-50 | ≤45 | >800 |

- Application

| Designation of rolls | Material code | Application |

| Zu60CMoMn | AS60 | Bar, wire, strip, steel roughing |

| Zu60CrMoMnNi | AS60 I | Bar, wire, strip, steel roughing |

| Zu65CrNiMo | AS65 I | Bar, wire, strip, steel roughing |

| Zu70Mn | AS70 | Bar, wire, strip, steel roughing |

| Zu70Mn2 | AS70 I | Bar, wire, strip, steel roughing |

| Zu70Mn2Mo | AS70 II | Bar, wire, strip, steel roughing |

| Zu75CrMo | AS75 | Bar, wire, strip, steel rough rolling, narrow steel support roller |

| Zu75CrNiMnMo | AS75 I | Bar, wire, strip, steel rough rolling, narrow steel support roller |

- Semi-steel rolls

- Chemical Analysis

| Designation of rolls | Material code | C | Si | Mr | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| ZuB140CrNiMo | AD140 I | 1.30-1.50 | 0.30-0.60 | 0.70-1.10 | 0.50-1.20 | 0.80-1.20 | 0.20-0.60 |

| ZuB160CrNiMo | AD160 I | 1.50-1.70 | 0.30-0.60 | 0.80-1.30 | ≥0.20 | 0.80-2.00 | 0.20-0.60 |

| ZuB180CrNiMo | AD180 | 1.70-1.90 | 0.30-0.80 | 0.60-1.10 | 0.20-2.00 | 0.80-1.50 | 0.20-0.60 |

| ZuB190CrNiMo | AD190 | 1.80-2.00 | 0.30-0.80 | 0.60-1.20 | 1.00-2.00 | 1.50-3.50 | 0.20-0.50 |

| ZuB200CrNiMo | AD200 | 1.90-2.10 | 0.30-0.80 | 0.80-1.20 | 0.60-2.50 | 0.60-2.00 | 0.20-0.80 |

- Physical Properties

| Designation of rolls | Material code | Barrel hardness (HSD) | Neck hardness (HSD) | Tensife strength (Mpa) |

|---|---|---|---|---|

| ZuB140CrNiMo | AD140 I | 35-50 | ≤60 | 500-800 |

| ZuB160CrNiMo | AD160 I | 40-60 | ≤50 | 500-800 |

| ZuB180CrNiMo | AD180 | 45-60 | ≤50 | 450-700 |

| ZuB190CrNiMo | AD190 | 50-65 | ≤50 | 450-700 |

| ZuB200CrNiMo | AD200 | 50-65 | ≤50 | 450-700 |

- Application

| Designation of rolls | Material code | Application |

| ZuB140CrNiMo | AD140 I | Bar, wire, steel, strip rough rolling, the vertical roll |

| ZuB160CrNiMo | AD160 I | Bar, wire, steel, crude and rolled strip, vertical roller, roll rings, support roller |

| ZuB180CrNiMo | AD180 | Bar, wire, steel, crude and rolled strip, vertical roller, roll rings, support roller |

| ZuB190CrNiMo | AD190 | Bar, wire, steel, crude and rolled strip, vertical roller, roll rings, support roller |

| ZuB200CrNiMo | AD200 | Bar, wire, steel, crude and rolled strip, vertical roller, roll rings, support roller |

- Graphite steel rolls

- Chemical Analysis

| Designation of rolls | Material code | C | Si | Mn | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| ZuS140CrNiMo | GS140 | 1.30-1.50 | 1.30-1.60 | 0.50-0.80 | 0.40-0.70 | 0.20-0.50 | |

| ZuS160CrNiMo | GS160 | 1.50-1.70 | 0.30-1.50 | 0.60-1.00 | 0.20-1.00 | 0.50-1.50 | 0.20-0.30 |

| ZuS190CrNiMo | GS190 | 1.80-2.00 | 0.80-1.50 | 0.60-1.00 | 0.60-2.20 | 0.50-2.00 | 0.20-0.80 |

- Physical Properties

| Designation of rolls | Material code | Barrel hardness (HSD) | Neck hardness (HSD) | Tensile strength (Mpa) |

|---|---|---|---|---|

| ZuS140CrNiMo | GS140 | 36-46 | ≤46 | ≥540 |

| ZuS160CrNiMo | GS160 | 45-55 | ≤50 | ≥500 |

| ZuS190CrNiMo | GS190 | 50-65 | ≤50 | ≥450 |

- Application

| Designation of rolls | Matarial code | Application |

| ZuS140CrNiMo | GS140 | Small and medium steel, thick wire rod mill, hot strip rough roll, roller universal rolling mill |

| ZuS160CrNiMo | GS160 | Small and medium steel, thick wire rod mill, hot strip rough roll, roller universal rolling mill |

| ZuS190CrNiMo | GS190 | Small and medium steel, thick wire rod mill, hot strip rough roll, roller universal rolling mill |

- High - Chromium steel rolls

- Chemical Analysis

| Designation of rolls | Material code | C | Si | Mn | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| CS | HCrS | 1.00-1.80 | 0.40-1.00 | 0.50-1.00 | 8.00-15.00 | 0.50-1.50 | 1.50-4.50 |

- Physical Properties

| Designation of rolls | Material code | Barrel hardness (HSD) | Neck hardness (HSD) | Tensile strength (Mpa) |

|---|---|---|---|---|

| CS | HCrS | 70-85 | 35-45 | ≥450 |

- Application

| Designation of rolis | Material code | Application |

| CS | HCrS | Hot strip roughing and finishing work roll front, wide plate mill work roll; steel universal mill roll |

- High-speed steel rolls

- Chemical Analysis

| Designation of rolls | Material code | C | Si | Mo | Ni | Cr | Mo | V | W |

|---|---|---|---|---|---|---|---|---|---|

| HSS | HSS | 1.50-2.20 | 0.30-1.00 | 0.40-1.20 | 0.00-1.50 | 3.00-8.00 | 2.00-8.00 | 2.00-9.00 | 0.00-2.00 |

| S-HSS | S-HSS | 0.60-1.20 | 0.80-1.50 | 0.50-1.00 | 0.20-1.20 | 3.00-9.00 | 2.00-5.00 | 0.40-3.00 | 0.00-3.00 |

- Physical Properties

| Designation of rolls | Material code | Barrel hardness (HSD) | Roll neck strength (Mpa) | Tensile strength (Mpa) |

|---|---|---|---|---|

| HSS | HSS | 75-85 | 30-45 | 400-500 |

| S-HSS | S-HSS | 75-88 | 30-45 | 400-500 |

- Application

| Designation of rolls | Material code | Application |

| HSS | HSS | Rolled strip, bar finishing roller, high speed wire pre-finishing, steel roller universalrolling mill, wide plate mill work roll |

| S-HSS | S-HSS | Rough rolling hot strip mill work roll, cold rolled strip steel work roll, intermediate roll |

| Specification | Material | Product code | Barrel hardness (HSD) | |

|---|---|---|---|---|

| Finished frame mill roll, prefinished frame mill roll | Ф280-Ф550 | High-performance high speed steel | LMM01 | 82-88 |

| Cutting frame mill roll | Ф280-Ф550 | High-performance segmentation high speed steel | LMM02 | 75-78 |

| Pre-cutting frame milt rolf | Ф280-Ф550 | High-performance segmentation high speed steel | LMM03 | 78-81 |

- Quality Control

- Raw Material

• Only work with 2-3 qualified long-term suppliers

• Each batch of raw material has quality certificate

• Acceptance test on receipt by our own laboratory

• Annual audit evaluation to all suppliers

- Test & Inspection

• Well equipped chemical and physical labs

• Standard test and inspection procedures

Records and samples are kept till roll scraped

• Final inspection done by QC Dept of third party

- Quality Staff

• Advanced and mature process as shown previously Technical confirmation during Heat Treatment process

• Most of equipments are computer-controlled

Standard operation guided by specified process cards

• Traceable operation records

- Manufacturing Process

• Well-trained and certified

• Main technical staff and key workers are with over 20 years experience in roll industry