Universal Carden Saft

Home » Our Products » Melting Shop Solutions » Universal Carden Saft

our products

Universal Carden Saft

get in touch

At Infinity Steel Industries Resources, we are committed to providing seamless communication and exceptional customer service. Whether you have questions about our products, need technical assistance, or are interested in exploring how we can support your steel manufacturing needs, our team is ready to assist you.

Refresh Your Day with Universal Carden Saft

- Diverse Industrial & Automotive Applications

Heavy Shock Load

Pulp & Paper Industry

Steel Rolling & Tube Mills, Corrugated Box Mfg. Co. Sewage Pumping Stations, Conveyer Primary Drives, Cement Industries

Tube Straitening Machines

Medium Shock Load

TMT Manufacturers

Vibrating Screens

Self Loading Transit Mixer

DTH-Water Well Drilling Rigs Road Construction Equip. Machinery

Auxiliary Drives

Transfer Trolley Roller Tables

Light Shock Load

PTO-Pump Drive Propeller Shafts Printing & Packaging Industry

Textile Machinery

Rip Saw Wood Working machines

Balancing Machines Diamond Wire Saw Machines

Farm Equipments & Tractor-Loaders

- How Do I Select A Suitable Cardan Shaft ?

Understanding the Mechanism of Cardan Shafts and the Growth in its Application!

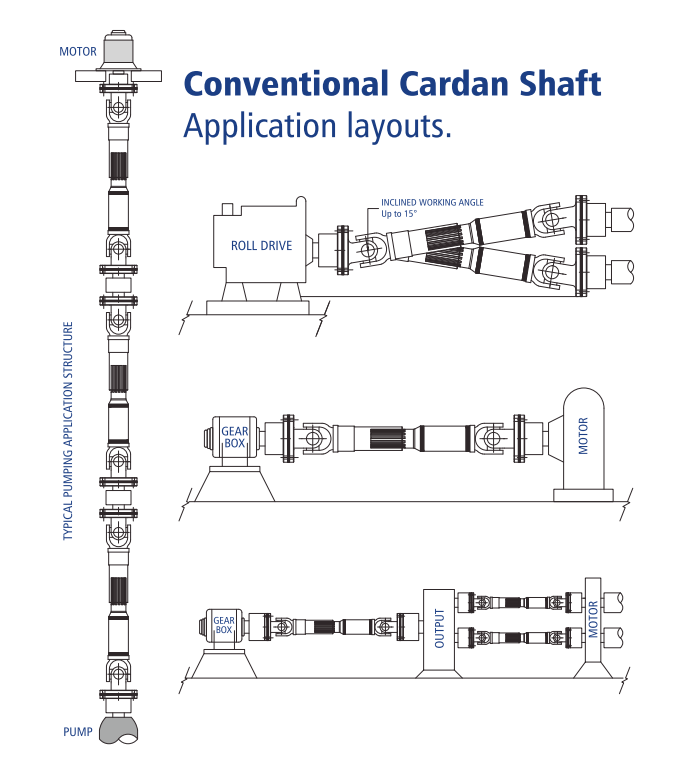

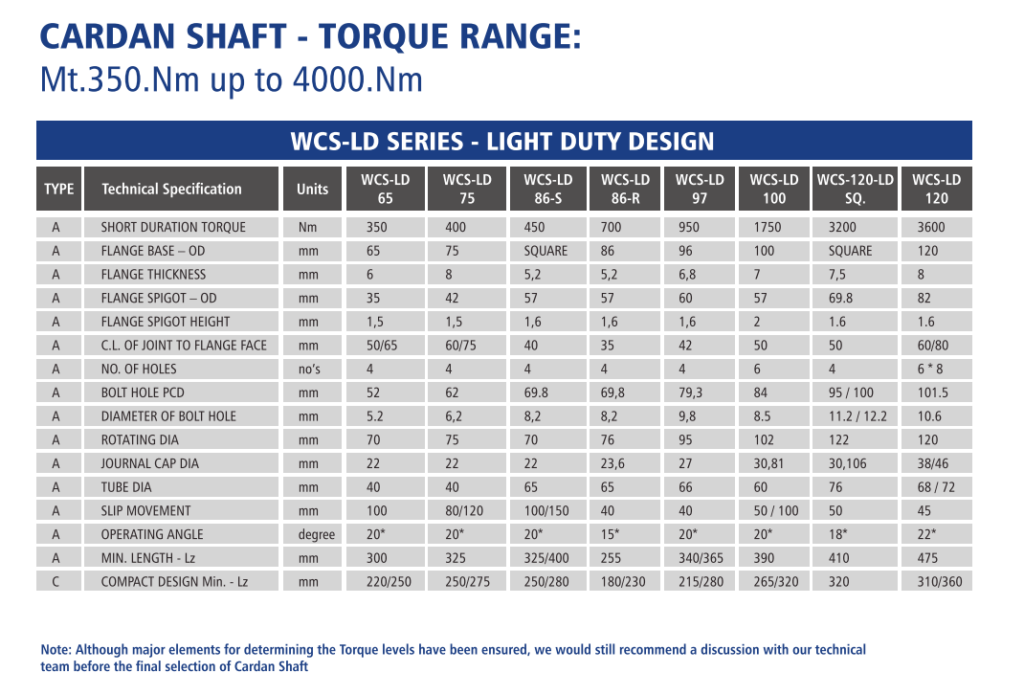

Cardan Shaft is defined as a motorized machine that can transmit torque between the driven and the driving torque or rotational motion from one shaft to another at fixed and varied angles of intersection on the shaft axis. They are principally categorized by their torque indicators when used as a single joint while operating at angles greater than 0° which may be non-uniform or uniform confiding to their necessary applications.

Though, it is conventionally known that the one of the most unique and prominent feature of a Cardan Shaft is not only of handling misalignment capabilities up to 15″ or greater, which evidently is quite higher than the 6º potential of gear couplings and spindles, but, Also for applying it for high stress torque load applications and almost continuous operation in various mills today, is surely on the rise. As a consequence the requisitions for Cardan Shafts have increased significantly where high torque load transmission is mandatory.

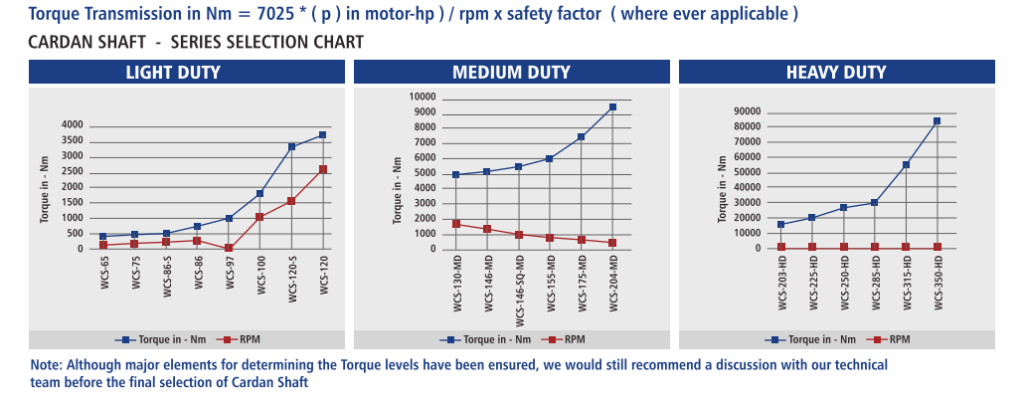

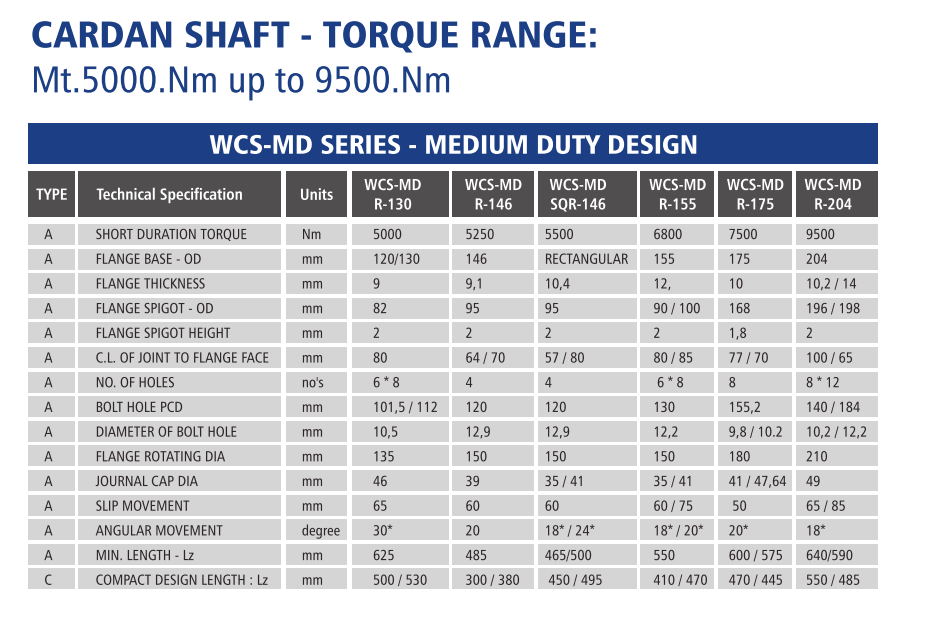

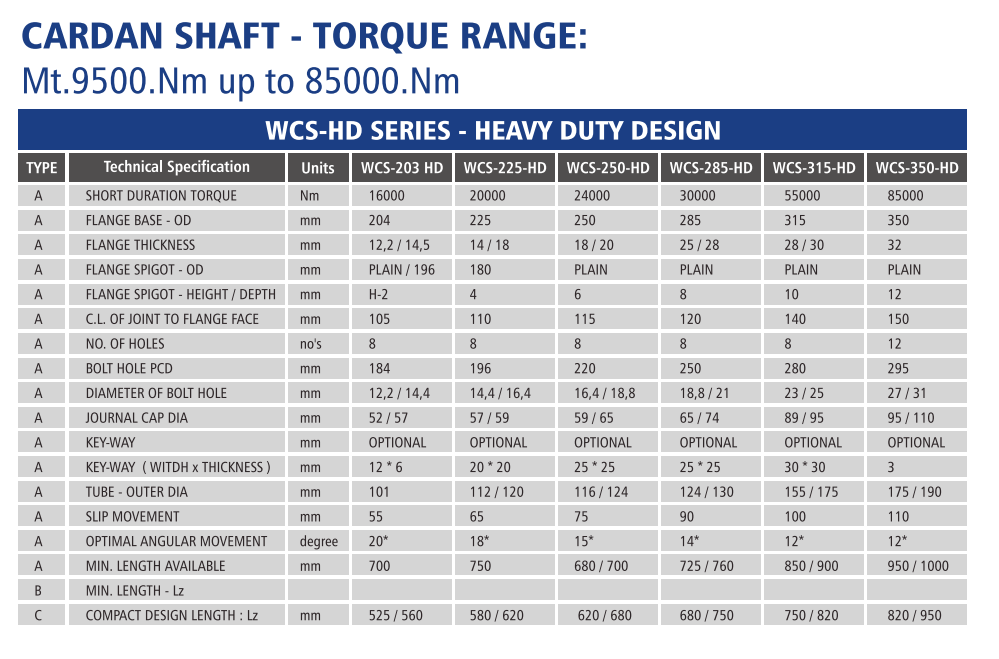

We are presenting for you a relatively simplified and universally approved torque determining technique which has been employed over the years by many Drive Shaft Manufacturing Companies that have been perusing a similar procedure while nominating to authorize a technically and efficient design of Cardan Shaft which would best suit your requirements. On the Cardan Shaft selection, it is necessary to assure that the rotating speed which is in function of the working angle is not too much high.

- Torque Calculation Technique

Suitable For The Paper & Pulp Mills Applications.

1. Basic Parameters required

(A) mpm – meters per minute, (B) rd – Roll Dia in mm, (C) p-Motor-HP.

2. Determining the Circular Movement = (cm) of the Roll by using the following technique. cm = rd*π (3.1416)

3. Method for calculating the RPM = mpm/cm* 1000

4. Nominal Torque (Nm) Rating Calculation method: Nm = 7,025 x hp/rpm

5. Closed and Expansion Length Measurement Observations must be drawn from the actual working conditions.

6. Safety Factors to be considered where applicable.

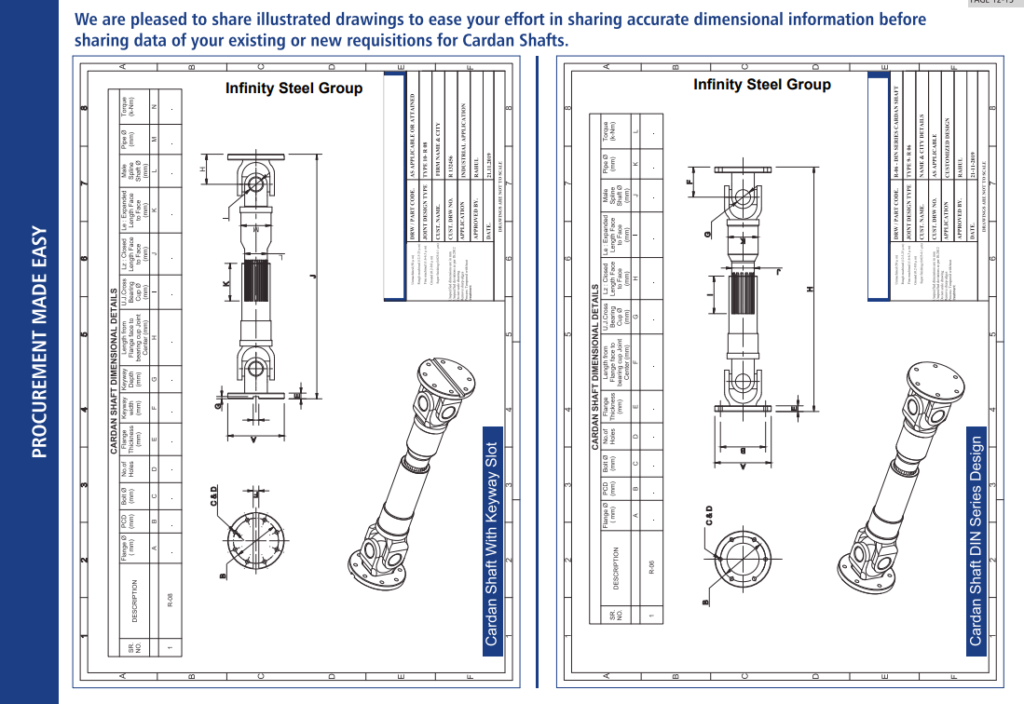

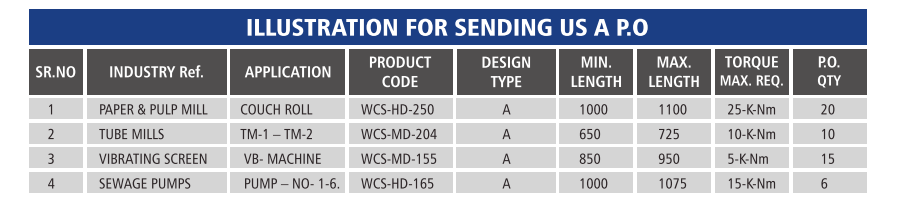

Please refer the below illustration for a better understanding

Basic parameters observed and received are: mpm = 200, Roll dia – 950.mm and the motor HP = 220

Step-1- Finding out the cm = circular dia = 950 x3.1416 = 2984.5

Step-2- Finding out the RPM = mpm/cm = 200/2984.5 x 1000 = 67

Step-3- Finding Nominal – Torque = 7025 x 220/67=23067 – Safety Factors may we considered where necessary.

- Installation Manual

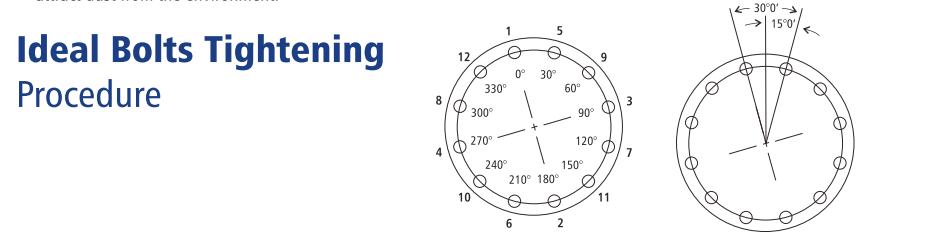

– Installing the Cardan Shafts requires skilled use of man power and we highly recommend that the responsible applicator should ideally be a skilled one. All traces of dirt, rust inhibitor and grease must be removed from the surface of the old flange to preserve the coefficient of friction which is vital for the torque transmission.

– Prior to the installation, it must be properly checked that they are assembled correctly which means that the marking rayson the spline shaft and the spline hub must face each other at the same angle.

– The necessary bolting hardware used should be equal in length, strength and should be suitable as per the holes of the Spline Companion Hub, Also, please ensure that play between the Flange Hole and Bolts used to fasten the Cardan Shafts should be within the permissible limits.

- Re-Lubricating Instructions

– The Cardan Shafts are normally provided with grease points, one on the Grease cup and the other one on the spline shaft.

– We highly recommend you to provide for a periodical lubrication both on the Bearing Caps and the Spline grooves, at an interval of 1-2 months, However, in case of Medium and Heavy Duty shafts, we recommend that the greasing process be carried out every 4-6 weeks for obtaining a longer life span of the universal joint cross bearings.

– Pumping of the grease on the bearings should ideally be carried out up to its emission from the bearings cap seals with a maximum pressure 15 bar. Further, after the greasing process is completed, excess grease must be wiped off from the bearing sides and it may attract dust from the environment.

- Reference Notes

Guidelines prior to placing a Purchase Order.

Special technical requests must be stated clearly in your valued Purchase Order forms and approval for the same is mandatory from our end.

1. Reference drawing incase of the existing Cardan Shafts (if available) may be submitted along with your requirement.

2. Any specific or Preferred Packaging Details – Wooden / Corrugated Boxes / Poly Bags – etc. may be updated to us.

3. Color Preferences (If any) must be mentioned separately.

4. Request for Anti-corrosion coating in case required must be stated in your order.

5. Room Temperature and working area conditions may be mentioned for a better understanding of the requirement.

6. The Lead Time must be clearly stated in your order form, so that any kind of delay is avoided.

7. Lubrication procedures may be well understood for obtaining a mature life cycle of the product.

8. Reference for use of High Tensile Fasteners are recommended, however, it may be consulted incase required.

9. Mode of material transit may be stated precisely along with your preferred dispatch destination.

10. Billing Name & Address, GST No, Any particular correspondence address should be precisely indicated.

10. Any preferred mode of Courier services may be mentioned clearly.

11. Your company’s E-Mailing addresses with mandatory cc-bcc address.

12. Name and contact details of the Technical & Commercially concerned persons may be shared for prompt communication.

- A TRIBUTE TO THE INVENTION OF CARDAN SHAFTS

A Brief history

In 1676, Robert Hooke revisited Italian Cardano’s idea to make use of an instrument that would allow them a safer way to study the sun. This unique instrument used a new type of joint that allowed a twisting motion in one shaft to be passed on to another, no matter how the two shafts were oriented. However, it took another 240 years for Clarence W. Spicer to come along and apply this idea to the automotive and industrial industries. Spicer received a patent for the universal joint in 1903 and demonstrated his new patent in a self-designed car, which did not have a troublesome chain & sprocket nor did it have chain and geared adaptions. However, the company eventually began the complete manufacturing in 1904. Since then, it has been innovation & development all the way from the automotive to the industrial sector as well.