Induction Furnace Spares

Home » Our Products » Melting Shop Solutions » Induction Furnace Spares

our products

Induction Furnace Spares

get in touch

At Infinity Steel Industries Resources, we are committed to providing seamless communication and exceptional customer service. Whether you have questions about our products, need technical assistance, or are interested in exploring how we can support your steel manufacturing needs, our team is ready to assist you.

Induction Furnace Spare Parts for Maximum Efficiency

- Induction Melting Furnace Coil:

Our induction coils are made from 99% ETH grade copper hollow (square or round) tube. Our energy efficient design allows maximum current draw per Kilowatt.

We offer a wide range of comparable OEM coils such as Inductotherm, Ajax-Tocco, Electrotherm, etc. ranging from 50KW thru 7500KW.

Our design engineers match our induction coils to your existing power supply unit per your provided diagrams and schematics.

We also offer a full line of furnace replacement spare parts such as copper wound tubing, coil supports, coil connections, brass CSK nuts/bolts to complete ready to line furnaces.

- How to reduce power consumption

By Increasing Coil Diameter & Revise Coil Conductor

Saves Power Consumption.

Example: 7ton/2500KW.

Existing Coil Diameter 46 inches.

Daily KWH Consumed 55510 units (Total 12 heats/day)

Taken average heat size 7200Kg

Total Production Achieved/day-7200X12=86400Kg

Unit consumed/ton-55510 KWHX 1000

86400 Kg

=642.47

Lets round up to 643 units/ton

By increased Coil diameter with New Design to 48 inches.

We achieve average heat size of 8072Kg, Say-8050Kg.

Heats achieved daily-11

Average Production achieved/day: 8050X11-88550Kg.

- Melting Induction Power Supply & Furnace:

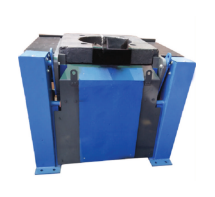

SOLID STATE POWER SUPPLY

We design and manufacture Solid State Power supply units for melting/heating applications for foundry & steel plants. We can provide the following power ratings.

Single Track & Dual Track TYPE:

75kw, 125kw, 175kw, 200kw, 250kw, 350kw, 450kw, 550kw, 750kw, 1000kw, 1250kw, 1500kw, 2000kw, 3000kw, 4000kw, 6000kw, Single Track & Dual Track type.

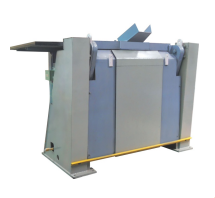

CORELESS / STEEL FRAME INDUCTION MELTING FURNACE

We manufacture all kinds of Duraline Coreless induction melting furnaces as well as Steel frame furnaces to match your existing inverter power supply or any customized requirements.

50kg, 100kg, 150kg, 250kg, 300kg, 500kg, 750kg, 1000kg, 1500kg, 2000kg, 3000kg, 4/5 ton, 6 ton, 7 ton,8 ton ,10 ton, 15 ton, 20 ton

COMPLETE FURNACE ASSEMBLY MATCHING WITH ANY KW POWER SUPPLY UNIT

Since our inception in 2009, we have successfully been engaged in manufacturing, exporting and supplying a wide range of high quality induction melting furnace assemblies. We have supplied such assemblies in modern foundries, steel shops and rolling mills all over the world, matching any KW power supply of Inductotherm, Electrotherm, or Ajex-Tocco type. Assemblies are manufactured by utilizing high grade components and latest techniques under expert’ guidance at our premises. In addition, upgrades and modifications of your existing design can be made upon your request providing more reliability and ruggedness to extend furnace life. Ranges from 5 kg to 25 ton capacity.

Features:

- Heavy and Robust construction

- High performance

- Easy for maintenance

- Longer service life

- Power Efficient Design

Our company specializes in manufacturing and exporting high-quality induction furnaces, which are widely used in steel manufacturing industries for the melting and refining of various types of metals. With our advanced technology and expertise in the field, we offer a diverse range of induction furnaces that cater to the specific needs and requirements of our customers.

Induction furnaces are known for their energy efficiency, rapid melting capabilities, and precise temperature control, making them a preferred choice for modern steel manufacturing processes. They utilize the principle of electromagnetic induction to generate heat within the metal charge, resulting in efficient and uniform melting.

- Range of Induction Furnaces:

1. Coreless Induction Furnaces:

– Capacity: Our coreless induction furnaces are available in a wide range of capacities, starting from small-scale units suitable for laboratory applications to large-scale furnaces capable of melting several tons of metal.

– Power Options: We offer coreless induction furnaces with various power options, allowing flexibility based on the specific requirements of the steel manufacturing operation.

2. Channel Induction Furnaces:

– Capacity: Our channel induction furnaces are designed to handle medium to large-scale metal melting processes. They are available in different capacities to suit the production requirements of our customers.

– Efficiency: These furnaces are known for their high thermal efficiency, ensuring effective utilization of energy and reduced operating costs.

3. Crucible Induction Furnaces:

– Capacity: Crucible induction furnaces are suitable for small-scale melting operations and are available in different capacities, typically ranging from a few kilograms to a few hundred kilograms.

– Portability: These furnaces are often compact and portable, making them suitable for applications where mobility and flexibility are required.

- Key Features and Benefits:

1. Energy Efficiency:

– Induction furnaces offer high energy efficiency due to the direct transfer of heat to the metal charge, minimizing heat loss and optimizing power consumption.

2. Fast Melting and Precise Temperature Control:

– Induction furnaces enable rapid melting of metals, resulting in increased productivity and shorter processing cycles.

– The advanced control systems ensure precise temperature control, allowing for accurate heat treatment and alloying processes.

3. Clean and Environmentally Friendly:

– Induction furnaces operate without the need for fossil fuels, reducing emissions and promoting a cleaner manufacturing environment.

– They generate minimal smoke, dust, and noise pollution, contributing to a healthier workplace.

4. Versatility and Flexibility:

– Induction furnaces can handle a wide range of metals and alloys, making them suitable for various applications in the steel manufacturing industry.

– They can be easily customized and adapted to meet specific melting requirements, allowing for flexibility in production processes.

5. Reliability and Durability:

– Our induction furnaces are built with high-quality materials and components, ensuring long-lasting performance and durability in demanding industrial environments.

– They undergo rigorous quality checks to ensure compliance with international standards and customer expectations.

6. Safety Features:

– Induction furnaces are equipped with advanced safety features, such as temperature monitoring systems, emergency shut-off mechanisms, and protection against power fluctuations, ensuring safe and efficient operation.

- Conclusion:

Our induction furnaces are designed and manufactured to deliver superior performance, energy efficiency, and reliability for the melting and refining of metals in steel manufacturing industries. With our diverse range of induction furnaces and commitment to quality, we provide customized solutions that meet the specific needs of our customers. Contact us today to explore how our induction furnaces can enhance your steel manufacturing operations.

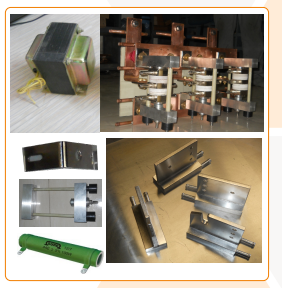

- Electromagnetic Components

We manufacturing and supply a wide range of Electromagnetic Components. We manufacture the components using optimum grade raw materials sourced from certified vendors. Our clients can order our Electromagnetic Components in different sizes and specifications as per their requirements and original furnace manufacturer standards:

Features

- Compact designed

- Durable quality

- Quality materials

- Magnetic Yoke / Shunts

Supported by a group of highly qualified & experienced engineers, supplying an exclusive range of Magnetic Shunt/Yokes of any size of major furnace manufacture with the same dimensions and quality. We manufacture the yoke, using high quality raw materials, procured from the most reliable and trusted vendors. Our Magnetic Yoke is available in different models and specifications as per the client’s requirements.

Features

- Easy to use/fitment.

- Sturdy design for long life.

- Durable quality of CRGO/CRNGO stamping.

- Quality Insulation

- Electronics Circuit Control Boards & Modules

We manufacture and repair Inductotherm, Ajax-Tocco Electrotherm and other brands of furnace panel circuit boards.

1. Main control board

2. Inverter firing circuit board

3. Converter firing circuit board

4. Ground leak detector modules

5. Monitor boards 6. Various types of potential sensors.

7. Short circuit protection modules

8. ACI

9. Opto bridge module

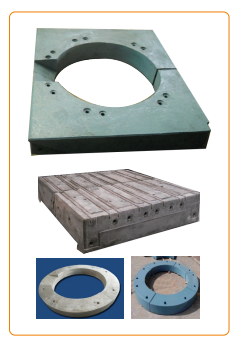

- Refractory Castable Top / bottom Blocks

Having an knowledge & expertise in the this industry, we are a renowned manufacturer and supplier of Refractory Castable Top/bottom Block used in industrial fumaces To comply with the set industrial norms, we use the finest quality materials to manufacture the blocks. Our quality inspectors check the Refractory Castable Top/bottom Block for durability and finishing parameters to offer a flawless product to the client. We are a manufacturer and supplier of all kinds of furnaces castable blocks for Inductotherm, Electrotherm, Ajex Tocco, Megatherm Furnace.

Features

- Rugged design

- Crack free finishing

- Easy to assemble

- Spare Part Induction Furnace

To keep pace with the fast changing trends of the industry and customer demands, we are engaged in manufacturing and supplying an extensive range of Spare Part Induction Furnace. These parts are manufactured under the strict supervision of the expert professionals using high quality materials, sourced from reliable vendors. The parts are made available for the clients in different sizes, diameters and finishing as to suit the client’s requirements

and we offer our spare part induction furnace at reasonable prices. Standards of major all manufacturer of furnaces like Inductotherm, Electrotherm, Ajex Tocco, Megatherm etc.

Features

- Rust proof finishing

- Durable quality

- Genuine raw material and reliable

- Technically match at existing machine.

- Semiconductor Fuse and Thyristors

We have a strong presence in the market by supplying excellent quality IGBT Transistor, Semiconductor fuses, SCRs, Diodes, etc of known brands used in Induction furnaces. Our team checks for high quality materials, procured from the most authentic vendors. We carry all available sizes of SCRs, Diodes and semiconductor fuse.

Features

- Resistant to impact and long last performance at optimum load

- Over rating designed to handle extra electrical stress.

- Matching with existing electrical systems design

- Insulation Material

We supply an extensive range of insulation material. These materials are used in melting and heating furnaces for insulation purposes. Our quality inspectors check the insulation material on certain quality parameters before delivering to our clients at the competitive rates.

Types of such materials are……

1. Silicon rubber tapes

2. Fibre glass insulations tape

3. Wovan tape

4. Flexocoat base and hardner for coal coating, FRP Varnish

5. Polyester resin or varnish

6. Every type of Epoxy resin material used in various applications.

7. FRP spacer used in separation of coil turns.

- Hydraulics Cylinders, Seal Kits, Flexible Hoses

We offer following types of Hydraulic Cylinder for Induction Melting Furnace application:

Tilting Hydraulic Cylinder of any KG, any make of induction furnace

Hydraulic Cylinder Rod end bearing blocks

Hydraulic Push out Mechanism Cylinder

Hydraulic Lid Mechanism Cylinder

Seal Kits are available for all above types of Hydraulic Cylinder

Non conductive Flexible hose used for hydraulic pipe line and its all type of fittings.

- Selector Switches

Our high quality Furnace Selector/Input Isolation Switches for Inductotherm, Electrotherm, Ajex Tocco, Megatherm. These switched are manufactured in compliance with set industrial norms, using only high quality materials. Available in different sizes, models and finishing, these switches are used in various furnace manufacturer models. We offer our Furnace Selector Switches at cost effective prices to the clients and deliver within the committed time frame.

Features

- Corrosion proof finishing

- Sturdy construction

- Longer service life

- Electrically/Mechanically tested at set up.

- Power Supply Spares

These are specially designed and dimensionally suitable to match with machines parameters without deviating the performance and maintain the quality of OEM Suppliers.

Just a few examples of what we can supply:

1. Thyristor clamp Assembly.

2. Chiiler device of Thyristors/IGBT

3. Insualting bushes used in clamp Assembly

4. Hardware of clamp Assembly

5. Various type of Teflon and Fiber sleeve wires used

6. Panel meters

7. Gauges, thermostat or sensors used

- Various Parts used in Furnace Assembly

These are specially designed and dimensionally accurate to fit without deviation of technical parameters with te OEM furnace manufacturers.

1. Pouring Spout

2. Cylinder cover and rod end bearing of pivot.

3. Various sizes of SS tie rods

4. SS hardware like nut bolt and other parts

5. Front and back covers of furnace

6. Platform support and its part

7. Insulating sheets and parts used at various places.

8. Trunnion pivot bearing etc.