Continuous Casting Machines

Home » Our Products » Melting Shop Solutions » Continuous Casting Machines

our products

Continuous Casting Machines

get in touch

At Infinity Steel Industries Resources, we are committed to providing seamless communication and exceptional customer service. Whether you have questions about our products, need technical assistance, or are interested in exploring how we can support your steel manufacturing needs, our team is ready to assist you.

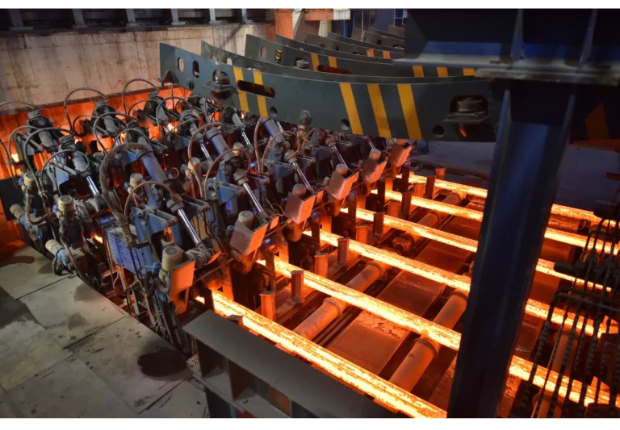

Superior Continuous Casting Machines for Streamlined Steel Manufacturing Operations

Our products are crucial equipment used in the steel manufacturing industry to convert molten steel into solidified steel billets, slabs, or other cast products in a continuous and automated process. They play a pivotal role in improving efficiency, productivity, and quality in steel production. As a leading manufacturer and exporter, we offer a comprehensive range of continuous casting machines designed to meet the specific requirements of steel manufacturing industries.

- Range of Continuous Casting Machines:

1. Machine Types:

– We provide a variety of continuous casting machine types, including vertical continuous casting machines and horizontal continuous casting machines.

– The selection of machine type depends on the specific casting requirements, such as product dimensions, steel grade, and production capacity.

2. Casting Formats:

– Our products support various casting formats, including billet casting, slab casting, bloom casting, and beam blank casting.

– They are designed to accommodate the specific dimensions and shapes required for different steel products.

3. Casting Processes:

– Our products offer different casting processes, such as strand casting and mold oscillation casting.

– These processes ensure controlled solidification and uniformity of the cast steel, resulting in high-quality products.

- Key Features and Benefits of Continuous Casting Machines:

1. High Productivity:

– Our products enable the continuous and automated production of steel products, significantly increasing productivity compared to traditional batch casting methods.

– They allow for a continuous flow of molten steel, minimizing downtime and maximizing output.

2. Improved Quality:

– The controlled casting process of continuous casting machines ensures uniform solidification and reduces the formation of defects in the cast steel.

– This results in improved product quality, including better surface finish, reduced segregation, and enhanced mechanical properties.

3. Energy Efficiency:

– Our products are designed with energy-saving features, such as optimized cooling systems and insulation materials.

– These features contribute to energy efficiency and reduce overall production costs.

4. Flexibility and Customization:

– Our products can be customized to meet specific requirements, such as casting dimensions, steel grades, and process parameters.

– We work closely with our clients to understand their unique needs and provide tailored solutions that optimize the continuous casting process.

- Applications:

1. Steel Mills:

– Our products are extensively used in steel mills for the production of steel billets, slabs, or other cast products

– They are an integral part of the steelmaking process, allowing for continuous and efficient casting operations.

2. Steel Foundries:

– Our products find applications in steel foundries that utilize continuous casting processes.

– They enable the production of high-quality castings with consistent properties, supporting various industries such as automotive, construction, and manufacturing.

3. Specialized Steel Production:

– Our products are employed in the production of specialized steel products, including alloy steels, stainless steels, and high-performance steels.

– They allow for precise control over the casting parameters, ensuring the production of steel products with desired characteristics.

- Conclusion:

Our products are essential equipment in the steel manufacturing industry, enabling the continuous and automated conversion of molten steel into solidified steel products. Our range of continuous casting machines offers high productivity, improved quality, energy efficiency, and customization options. Whether used in steel mills, steel foundries, or specialized steel production, our continuous casting machines are designed to deliver exceptional performance, reliability, and efficiency. We are committed to providing innovative solutions that optimize the continuous casting process and contribute to the success of our clients in the steel manufacturing industry.