Copper Mould

Home » Our Products » Copper Mould

our products

Copper Mould

get in touch

At Infinity Steel Industries Resources, we are committed to providing seamless communication and exceptional customer service. Whether you have questions about our products, need technical assistance, or are interested in exploring how we can support your steel manufacturing needs, our team is ready to assist you.

High-Performance Copper Moulds for Metal Casting

- Equipment

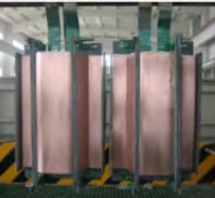

As the old saying goes, one must sharpen his tool before going to make a perfect work ,our company spends heavily on the manufacturing equipment of copper mould tubes and plates. Now we have 9 sets of large, medium, and small hydraulic press, 30 sets of CNC machine centers, 2 sets special CNC processing machines, We have complete electroplating facilities, first class electro-plating equipment, and up-to-date electro-plating technologies. We have two electro-plating workshops for mould tube plating and mould plates plating separately and each of them covers an area of 1800 square meters. There are 32 tanks for Cr plating of mould tubes and 7 tanks for plating of mould plates. The maximum siza of round tubes that can be plated is up to Dia.1500mm and the widest mould plates can be plated is up to 3800mm. We have advanced watertreatment system. We adhere strictly to the environmental policy of zero emission which makes our company a green and environment-preserving enterprise.

| Process | Equipment | Quantity |

| Smelting/Casing | Smelting furnace and continuous casting machine | 2 line |

| Forging/Extrusion | Hydraulic Press | 9 sets |

| Machining | CNC Machines | 23 various units |

| Special CNC Processing Machines | 2 Sets | |

| Electro-plating | Copper Annealing Fumace | 1 line |

| One electro plating Line for tube and plate each | 2 lines | |

| Quality Assurance | Tensile Strength Machine | 1 set |

| Harness meters | 5 sets | |

| Thickness meters | 2 sets | |

| Ultrasonic flaw detection machine | 1 sets |

- Material

TP2 is a kind of material is selected by most of the steel plants. It shows excellent heat-proof and anti-fatigue property under high temperature and it has good processing property.

CuAg0.1 is adding 0.08%-0.12% silver during copper ingots melting will increase the recrystallization temperature of copper by 100C, which will increase the heat stress and anti-abrasive property of copper mould tube interior surface, showing better he-atresistant property than TP2.

Cu-Cr-Zr is a kind of copper allys which can be normalized by time. It has excellent mechanical property under both room tem-perature and hight temperature. It has hight heat conductivity, melting point, anti-fatigue and anti heat stress properties. Their out-standing features make it different from the previous copper alloys. It combines all good properties together. But compared with other copper alloys, Cu-Cr-Zr is difficult to be formed with higher products costs.

- Coating

| Material | |||||

|---|---|---|---|---|---|

| Item | Temp | Unit | Material | ||

| CuDHP | CuAg0.1 | CuCrZr | |||

| Chemical Composition | |||||

| P0.015-0.040 | Ag0.08-0.12 P0.004-0.012 | Cr0.30-1.20 Zr0.03-0.30 |

|||

| Physical properties | |||||

| Electical conductivity | 20 | %IACS | 83 | 95 | 80 |

| Thermal conductivity | 20 | W/(m. K) | 340 | 37 2 | 330 |

| Coefficient of thermal expansion | 20-300 | 10^-6/K | 17.1 | 17.1 | 17.2 |

| Recrystallisation temperature | °C | 345 | 360 | 690 | |

| Modulus of elasticity | 20 | 10^ 3MPa | 120 | 123 | 126 |

| Melting point | °C | 1083 | 1083 | 1078 | |

| Specific gravity | g/cm³ | 8.9 | 8.9 | 8.9 | |

| Mechanical properties. | |||||

| Ultimate tensile strength | 20 | Mpa | 240-310 | 240-310 | 375-44 5 |

| Ultimate tensile strength | 100 | Mpa | 190-270 | 230-270 | 365-425 |

| Ultimate tensile strength | 200 | Mpa | 140-190 | 205-240 | 365-410 |

| Ultimate tensile strength | 300 | Mpa | 175-210 | 335-375 | |

| Ultimate tensile strength | 400 | Mpa | 145-160 | 315-350 | |

| 0.2Yield point strength (Rp0. 2) | 20 | Mpa | 190-250 | 200-225 | 280-355 |

| 0.2Yield point strength (Rp0. 2) | 100 | Mpa | 185-260 | 195-240 | 270-345 |

| 0.2Yield point strength (Rp0. 2) | 200 | Mpa | 180-225 | 260-330 | |

| 0.2Yield point strength (Rp0. 2) | 300 | Mpa | 165-215 | 250-320 | |

| 0.2Yield point strength (Rp0. 2) | 400 | MPa | 130-145 | 240-290 | |

| Elongation (A5) | 20 | % | 25-10 | 16_10 | 20-13 |

| Hardness | 20 | HB | 80-95 | 110-125 | 115-130 |

| Mark: TP2 (GB/T5231-2001)= SF-Cu/DHP-Cu(DIN1 787) | |||||

Copper has lower hardness which leads to lower anti-abrasive property. Therefore, the area at the lower part of the moulds, where the stress increases drastically due to shells, will be more severelywon. To increase the life time of copper moulds, LMM provides uniform mould interior surface plating with suitable hard-ness. Most of the copper mould tubes for small size billet casting are not used in any casting system where there are rigid casting stream support, therefore they are very sensitive to be worn. We use hard chrome plating to increase the life of mould tubes. The plating thickness recommended by LMM will be controlled in the best range. As for the coating of copper mould plates, based on our years of experience, we are able to provide Cr coating, Ni-Cr coating, Ni-Fe coating and NiCo-Cr coating to meet the demand of various customers both at home and abroad.

- Research & Development

Our company has 50 technicians and 15 of them have senior professional titles. We have strong ability to develop products of various materials and sizes (Square, Rectangular, Round, Nonstandard and Beam Blanks, with range from the smallest of 50x50mm to the largest of Dia. 1500mm round tubes, 500x500mm Square tubes, 120×650 rectangular tubes). Strong R&D abilities can meet the customers demand to the maximum extent. The perfect combination of experience and theories constantly improves the quality of our products. We are dedicated to shaping steel! We not only provide products, we also provide handicrafts, the mirror finished tubes surface is like a mirror.

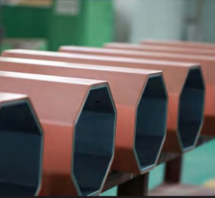

- Mould Tubes

| NAME | ITEM SIZE | CAMBER RADIUS | THICKNESS | LENGTH | REMARKS |

|---|---|---|---|---|---|

| Square & Rectangle Copper tubes | Square 50-50-650-650 Rectangle (100-500)×650 | 3000-17000 Also straight | 6-50 | 602-1100 | With slot single taper, double taper, triple taper, quadruplicate taper, parabolic taper and varius kinds of continuous taper high effciency copper mould tubes |

| Round copper tubes | 0110-01500 | 5000-17000 Also straight | 10-50 | 602-900 | With slot double taper, quadruplicate taper, parabolictaper and varius kinds of continuous taper high effciency copper mould tubes |

| Non-standard copper mould tubes Beam Blank copper mould tubes | 535-150-150-70 | 6000-14000 | 12-50 | 700-1016 | With slot single taper, double taper, triple taper. quadruplicatetaper, parabolic taper |

- Mould Plates

| COPPER PLATE SIZE | SPECIFICATIONS | MATERIAL | COATING | ||

| LENGTH | WIDTH | MATERIAL | |||

| Slab | 350-3800 | 700-1000 | 35-300 | Cr-Zr-Cu, CuAg | Ni-Co, Cr, Ni-Fe |

| Beam Blank | 350-900 | 300-1000 | 35-300 | Cr-Zr-Cu, CuAg | Ni-Co, Cr, Ni-Fe |

| Rectangle | 700-900 | 200-3000 | 30-70 | Cr-Zr-Cu, CuAg | Ni-Co, Cr, Ni-Fe |

| Thin Slab | 1200-2000 | 1100-1200 | Cr-Zr-Cu, CuAg | Ni-Co, Cr | |

| Ultra-thin Slab | 1530 | 700-900 | Cr-Zr-Cu, CuAg | Ni-Co, Cr | |

- Water Jacket

Water jackets are the cooling part of CCM mould assembly. LMM technical know-how and expe rience in the field has led to the realization that the design and reliability of the water jacket is es sential for the continuous casting

LMM can also provide a single piece stainless steel mould water jacket with light tolerances and the necessary thickness to avoid deformation. The highest quality standards ensure optimal

moulds tube performances and an easier mould installation and removal

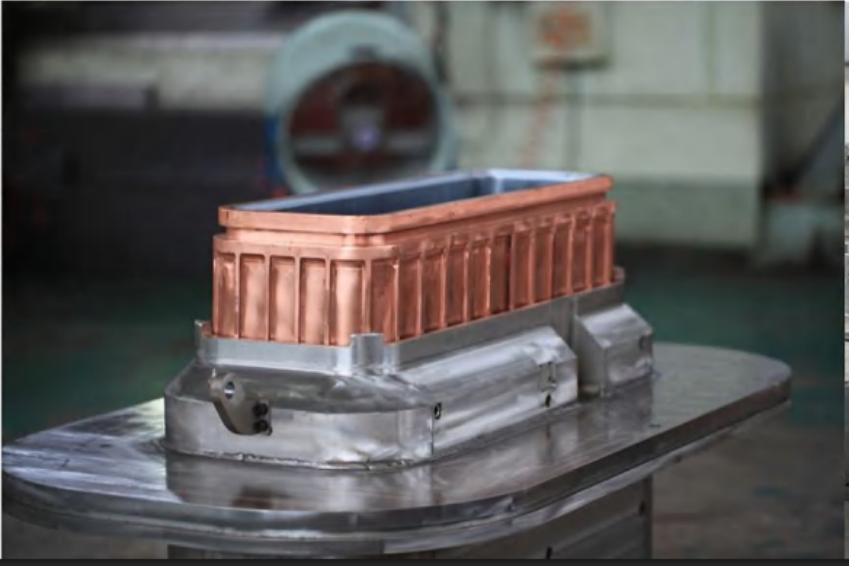

- Assembly

Mould assemblies are key equipment for continuous casting. We produce round, square, rectangular and beam blank mould assemblies of different sizes with material of stainless steel and carbon steel.

LMM GROUP Mould assemblies have vertical and curved types in structure, The precision of mould assemblies are guar-anteed as the forged stainless water jackets are produced by extrusion while assembled water jackets are machined by high precisionn CNC machines,

- Continuous casting machine

As the steel industry continues to improve quality and reduce cost, there is growing interest to maximize the productivity from a single continuous casting machine. We can design continuous casting machine to increase casting speed to help customers to save cost and improve production effi ciency

The target of our work is to improve our technological capacities to be in the inter-est of the customers. For the purpose, we have been dedicated to new products development, we established R & D department for new alloys, optimized copper taper and better anti-weaying coating. Our physical and chemical laboratories are equipped with advanced analysis and inspection sys tems which provides strong guarantee for the quality of our products.

Taper Measuring Apparatus, Main inspection instruments and meters.