Infinity Steel Industries Resources is a top Supplier and Exporter of Refractory Products in Kenya.

Headquartered in Ahmedabad, Gujarat, India, the company is ISO 9001:2015 certified, ensuring international standards of quality, reliability, and customer satisfaction.

Refractory products are specially engineered to withstand extremely high temperatures, thermal shocks, chemical corrosion, and mechanical stress in industrial environments.

They are essential for industries like steel, cement, glass, petrochemical, power, and non-ferrous metal production.

At Infinity Steel Industries Resources, we provide high-quality refractory solutions that deliver maximum durability, energy efficiency, and long service life for critical manufacturing processes.

We manufacture our products with advanced technology to meet global industry standards, ensuring superior performance in demanding conditions.

Industries use refractory products as heat-resistant materials to line furnaces, kilns, incinerators, reactors, and boilers.

They protect industrial equipment from intense heat, wear, and chemical reactions while maintaining strength and stability.

Without refractories, industries cannot achieve safe and efficient operations at high temperatures.

Features:

Exceptional Heat Resistance – Maintain structural integrity at high operating temperatures.

Thermal Shock Resistance – Withstand rapid temperature changes without fracturing.

Mechanical Strength – Strong under compressive or impact loads.

Chemical & Corrosion Resistance – Resist slags, fumes, and aggressive gases or molten materials.

Low Thermal Conductivity – Minimize heat transfer and improve energy efficiency.

Versatile & Customizable – We tailor formulations to your operational needs, whether high alumina content, insulating behavior, or unique furnace chemistry compatibility.

Applications:

Infinity Steel Industries Resources engineers refractory products to perform reliably in some of the most demanding industrial environments. Their applications span across multiple sectors, including:

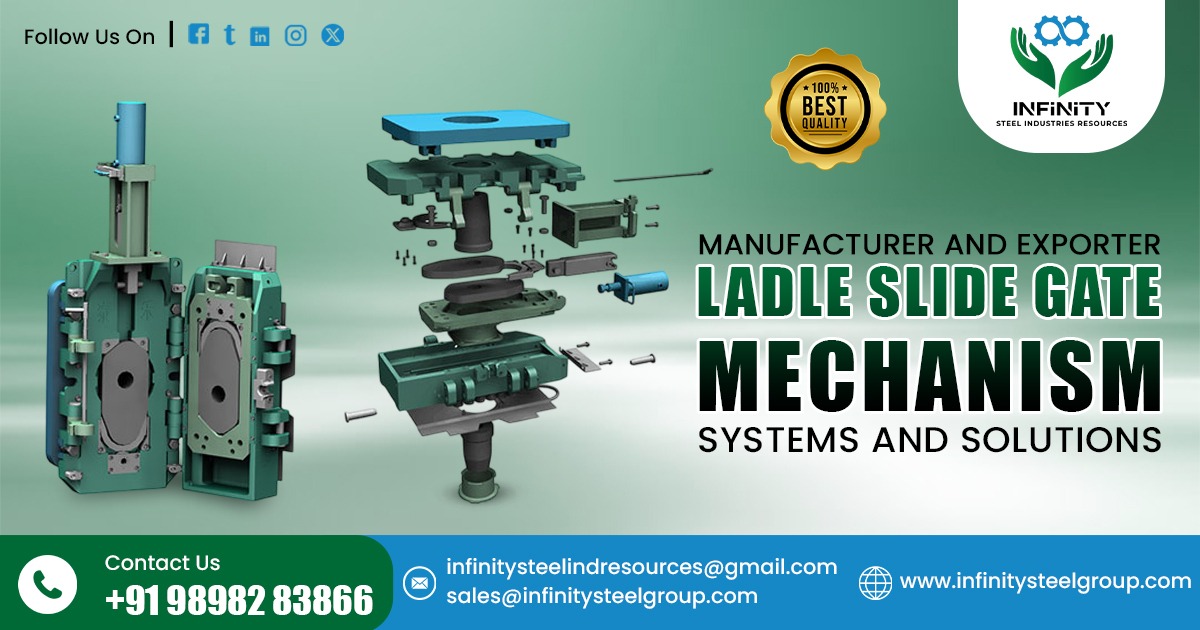

Steel Industry – Essential for furnace linings, ladles, converters, and tundishes.

Cement Plants – Used in kiln linings, coolers, and preheater duct insulation.

Glass Manufacturing – Ideal for glass furnaces, melting tanks, and regenerators.

Ceramic Industry – Applied in kilns, firing chambers, and heat-treatment units.

Power Plants – Provide durability in boilers, incinerators, and gasifiers.

Petrochemical Sector – Used in reactors, reformers, and cracking units.

Non-Ferrous Metallurgy – Suitable for smelters, converters, and refining equipment.

Frequently Asked Questions (FAQs):

Q: What are refractory products used for?

A: Industries use refractories to line high-temperature equipment—like furnaces, kilns, and reactors—to protect structural integrity and reduce heat loss.

Q: How do I choose the right refractory for my application?

A: Consider operating temperature, mechanical stress, chemical exposure (e.g., slags, flux), thermal cycling, and required service life. Our technical team helps select the optimal type—dense bricks, monolithics, or insulating materials.

Q: What types of refractories do you offer?

A: We provide dense and insulating fire bricks, high‑alumina, magnesia, silica refractories, castables (pumpable & hand‑place), gunning mixes, ramming masses, and ceramic fiber products.

Infinity Steel Industries Resources is a prominent Supplier and Exporter of Refractory Products in Kenya, including other locations Naragoi, Bungoma, Dadaab, Eldoret, Killfi, Kisil, Lamu, Litein, Lodwar, Lokichoggio, Mombasa, Moyale, Ruiru, Mumias, Nairobi, Nanyuki, Narok, Wajir, Watamu, Watamu, Webuye, Wote, Wundanyi.

For more information, please feel free to contact us.