Tundish and Tundish Car

As a leading manufacturer and exporter, we offer a comprehensive range of tundishes and tundish cars designed to meet the specific requirements of steel manufacturing industries.

- Home

- Products

- Melting Shop Solutions

- Tundish and Tundish Car

Our Products

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. or just call us now.

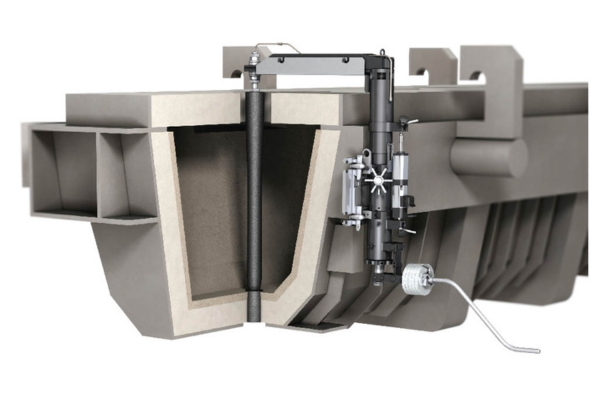

Tundish and Tundish Car Overview

The Tundish and Tundish car are essential components in the steel manufacturing industry, specifically in continuous casting processes. The tundish acts as a reservoir that holds and regulates the flow of molten steel from the ladle to the mold during casting, while the tundish car provides the mobility and support for the tundish. As a leading manufacturer and exporter, we offer a comprehensive range of tundishes and tundish cars designed to meet the specific requirements of steel manufacturing industries.

Range of Tundish

Flow

Regulation

The tundish acts as a reservoir, ensuring a constant and controlled flow of molten steel from the ladle to the mold.

It helps regulate the flow rate and temperature of the steel, allowing for smooth casting operations.

The tundish provides a settling zone where non-metallic inclusions and impurities can float to the top, allowing for their removal before the steel enters the mold.

This helps improve the quality and cleanliness of the cast steel.

Inclusion

Removal

Temperature

Homogenization

The tundish allows for temperature equalization, ensuring that the molten steel maintains a uniform temperature throughout the casting process.

This temperature homogenization minimizes thermal variations and promotes consistent solidification of the steel.

Range of Tundish Car

Mobility

The tundish car is designed for easy movement and positioning of the tundish within the continuous casting plant.

It is equipped with wheels or tracks and a drive system, allowing for smooth and precise transportation.

The tundish car provides a stable platform for the tundish, ensuring its proper positioning during the casting process.

It is designed to withstand the weight of the tundish and the thermal and mechanical stresses encountered during operation.

Stability &

Support

Tilting

Mechanism

Some tundish cars are equipped with a tilting mechanism, allowing for controlled pouring of the molten steel into the mold during casting.

The tilting feature enables precise control over the casting process and facilitates the formation of quality steel products.

Key Features and Benefits

Improved Casting Efficiency

The use of tundishes and tundish cars optimizes the continuous casting process, enhancing casting efficiency and productivity. They ensure a smooth and controlled flow of molten steel, minimizing interruptions and improving the overall casting yield.

Enhanced Steel Quality

Tundishes provide a means of inclusions removal, contributing to the production of high-quality and clean steel products. The temperature homogenization achieved in the tundish helps maintain consistent steel properties throughout the casting process.

Flexibility and Customization

Our range of tundishes and tundish cars can be customized to meet specific requirements, such as casting volume, design, and process parameters. We work closely with our clients to understand their unique needs and provide tailored solutions for their continuous casting operations.

Applications

Continuous Casting Plants

Tundishes and tundish cars are extensively used in continuous casting plants, which are common in steel manufacturing facilities. They play a critical role in ensuring a controlled and efficient flow of molten steel from the ladle to the mold, supporting the continuous production of steel billets, slabs, or other cast products.

Steel Foundries

Tundishes and tundish cars find applications in steel foundries that utilize continuous casting processes. They enable the controlled transfer of molten steel from the ladle to the mold, ensuring the production of high-quality castings with consistent properties.

Non-Ferrous Metal Casting

Tundishes and tundish cars are also used in non-ferrous metal casting processes, such as aluminum or copper casting. They facilitate the controlled flow of molten metal, allowing for the production of various non-ferrous metal products with precise dimensions and properties.

Specialized Steel Production

In specialized steel production processes, such as alloy steel or stainless steel production, tundishes and tundish cars are utilized. They contribute to the controlled casting of specific steel grades, allowing for the production of specialized steel products with desired characteristics.

Customized Applications

Apart from standard applications, our tundishes and tundish cars can be customized to meet specific requirements and applications within the steel manufacturing industry. We collaborate closely with our clients to understand their unique needs and provide tailored solutions that optimize the continuous casting process.

Tundishes and tundish cars are vital components in the continuous casting process within the steel manufacturing industry. Our range of tundishes ensures the regulated flow and temperature control of molten steel, improving casting efficiency and enhancing the quality of steel products. The tundish cars provide mobility and stability for the tundish, allowing for easy transportation and precise positioning during casting operations. With customization options, our tundishes and tundish cars can be tailored to meet specific requirements and applications, supporting continuous casting plants, steel foundries, non-ferrous metal casting, specialized steel production, and more. We are committed to delivering reliable, efficient, and customized solutions that optimize the continuous casting process for our clients in the steel manufacturing industry.